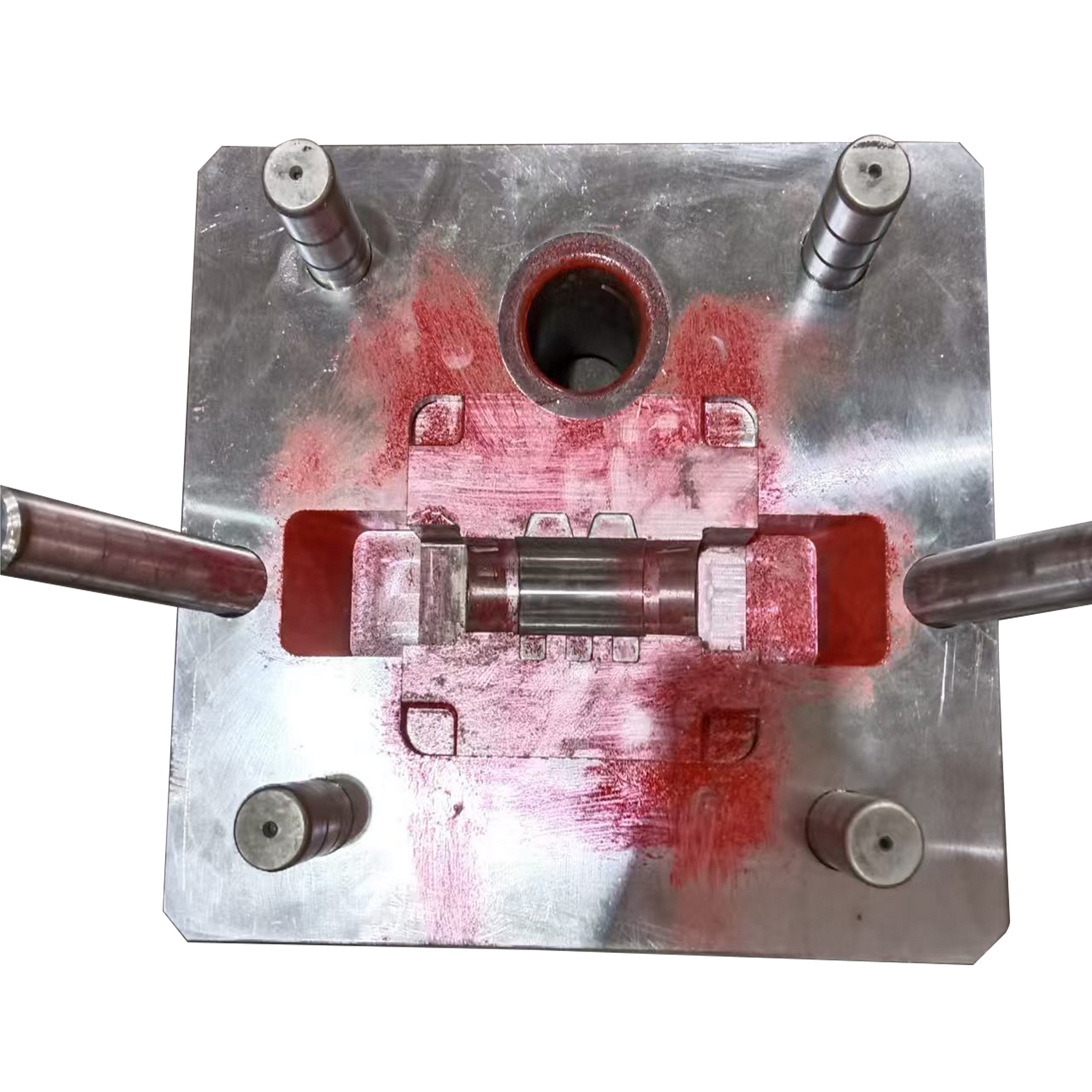

Custom metal molds are essential in various manufacturing processes, particularly in the production of components made from aluminum, zinc, and magnesium alloys. At Haoda, we specialize in creating molds that not only meet but exceed industry standards. Our molds are designed for precision and durability, ensuring that they can withstand the rigors of repeated use in high-volume production environments. Our automated melting and die-casting machines allow for uniformity and efficiency, reducing production time and costs. Furthermore, our CNC machines enable intricate designs that cater to specific customer requirements, ensuring that every mold is a perfect fit for its intended application. We also utilize advanced inspection technologies, such as CMM and X-ray real-time imaging, to ensure that each mold meets our stringent quality standards. Our commitment to customer satisfaction drives us to offer personalized services, ensuring that we address your unique needs effectively. Choose Haoda for your custom metal mold solutions and experience the difference in quality and service.