Custom molds for concrete are essential for various applications in construction and design. At Haoda (Ningbo) Import and Export Co., Ltd, we specialize in crafting molds that cater to a wide range of needs, from architectural elements to industrial components. Our molds are designed not only for functionality but also for aesthetic appeal, allowing you to create stunning concrete structures that stand out.

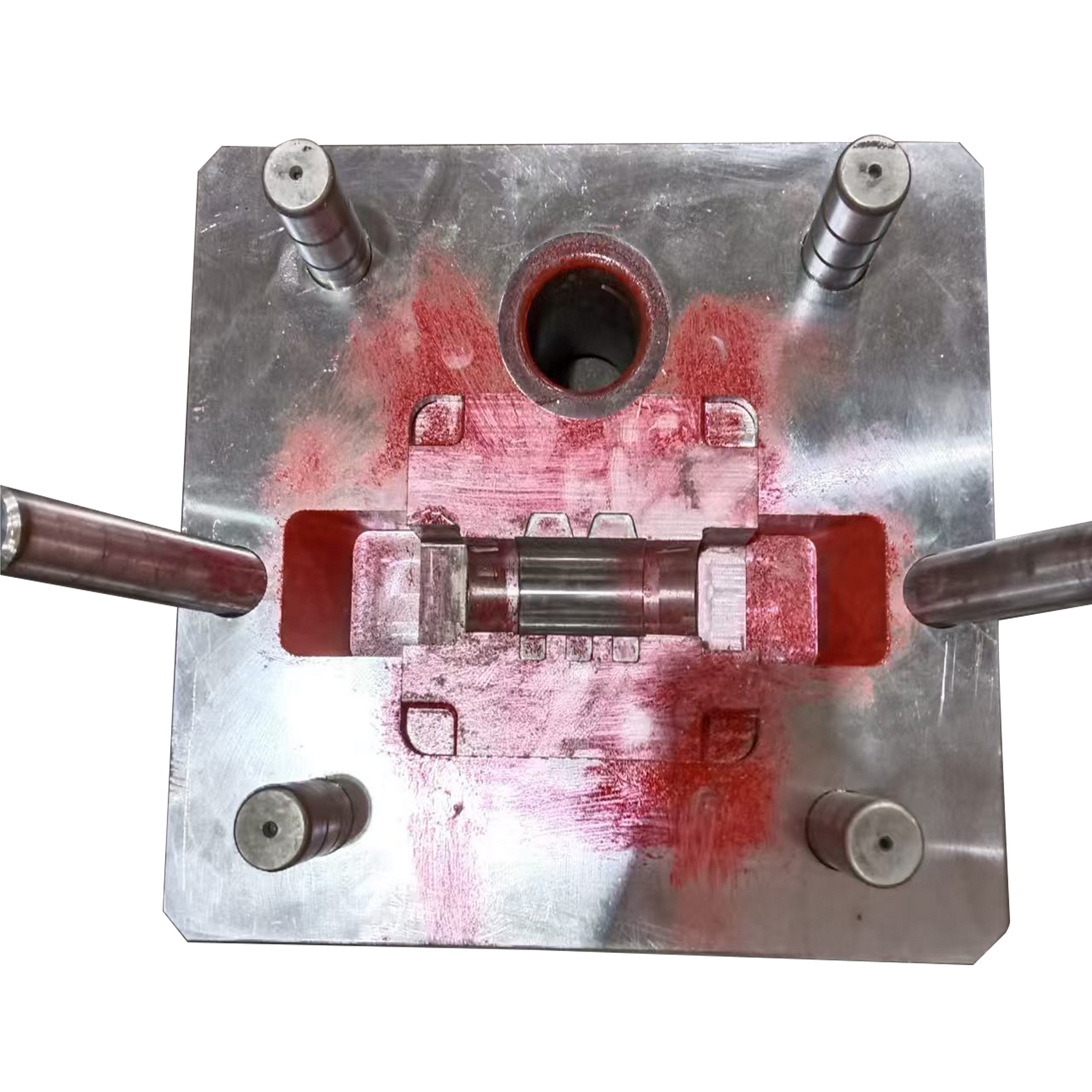

The process begins with understanding your specific requirements. We collaborate with you to determine the dimensions, shapes, and materials needed. Our state-of-the-art manufacturing equipment, including CNC machines and die-casting technology, ensures that every mold we produce meets the highest standards of precision and durability.

Moreover, our commitment to quality control means that each mold undergoes rigorous testing to ensure it can withstand the demands of concrete pouring and curing. We understand that the success of your project relies on the quality of the molds used, which is why we prioritize creating products that are reliable and long-lasting.

In addition, our molds are designed to be user-friendly, facilitating easy handling and concrete application. We also provide guidance on best practices for using our molds to maximize their effectiveness and ensure the best results in your concrete projects. Our customer-centric approach ensures that we are there to support you throughout the process, from initial consultation to final product delivery.