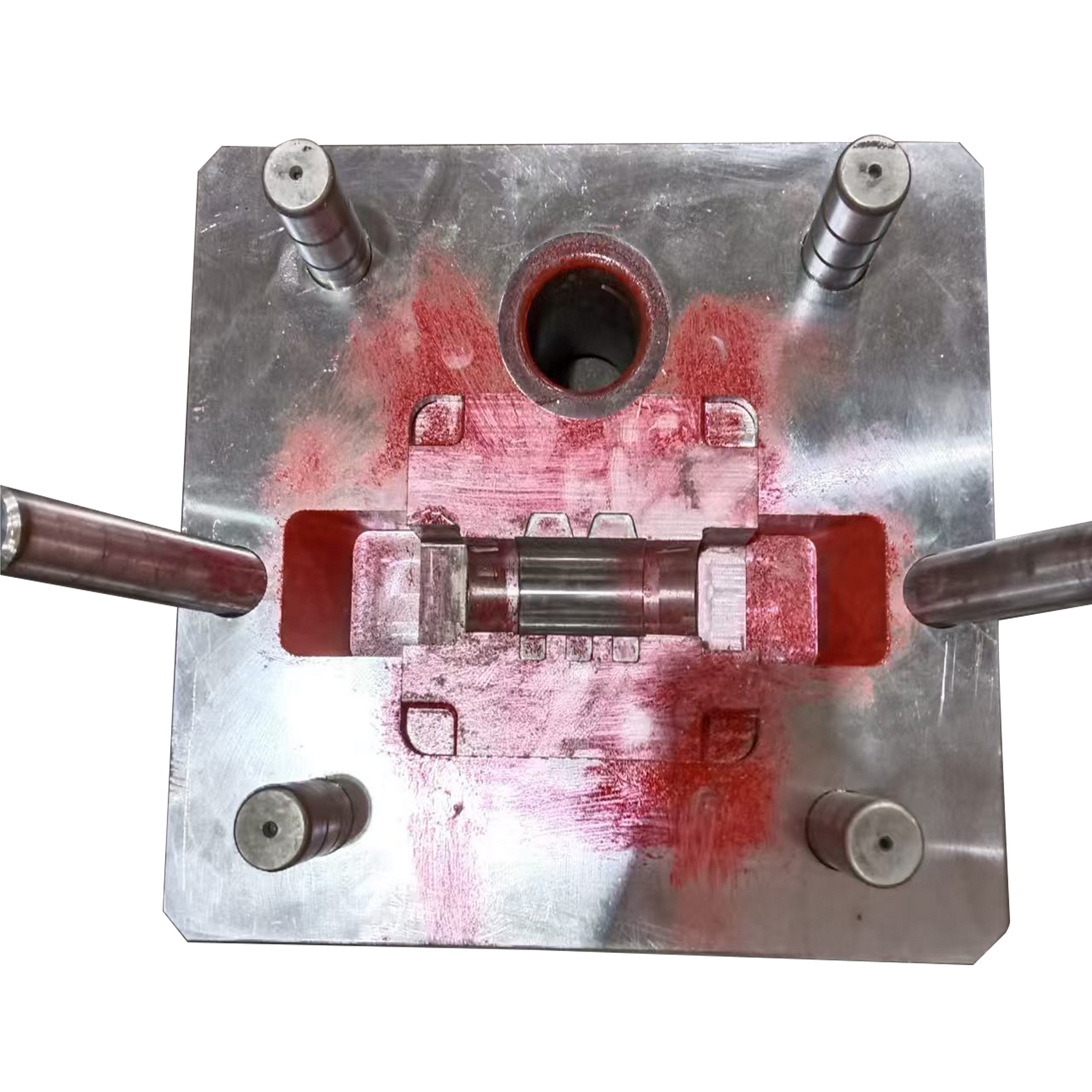

In the realm of manufacturing, the importance of high-quality, custom molds cannot be overstated. At Haoda (Ningbo) Import and Export Co., Ltd, we specialize in creating custom molds that cater to the unique needs of our clients in various industries. Our expertise lies in working with aluminum, zinc, and magnesium alloys, which are known for their lightweight and durable properties. These materials are ideal for a wide range of applications, from automotive parts to consumer electronics.Our custom mold making process begins with a thorough consultation, where we assess your specific requirements and project goals. We utilize advanced technology, including CNC machines and die-casting equipment, to produce molds that are not only precise but also efficient in production. Our team of skilled engineers applies their extensive knowledge to design molds that optimize material usage and minimize production time.

Furthermore, our commitment to quality is unwavering. We implement rigorous testing and quality assurance measures throughout the production process. This ensures that every mold we deliver meets the highest standards of performance and reliability. With our IATF16949 certification, you can trust that our products are manufactured with the utmost care and attention to detail.

Choosing Haoda as your custom mold maker means investing in a partnership that prioritizes your success. We understand the challenges faced by manufacturers and are dedicated to providing solutions that enhance your operational efficiency. Our customer-centric approach ensures that we are responsive to your needs, adapting our services to align with your production timelines and specifications.

In conclusion, our custom molds are designed to provide exceptional quality and performance, helping you achieve your manufacturing objectives. Whether you are looking for molds for small-scale projects or large production runs, Haoda is equipped to meet your needs with precision and expertise.