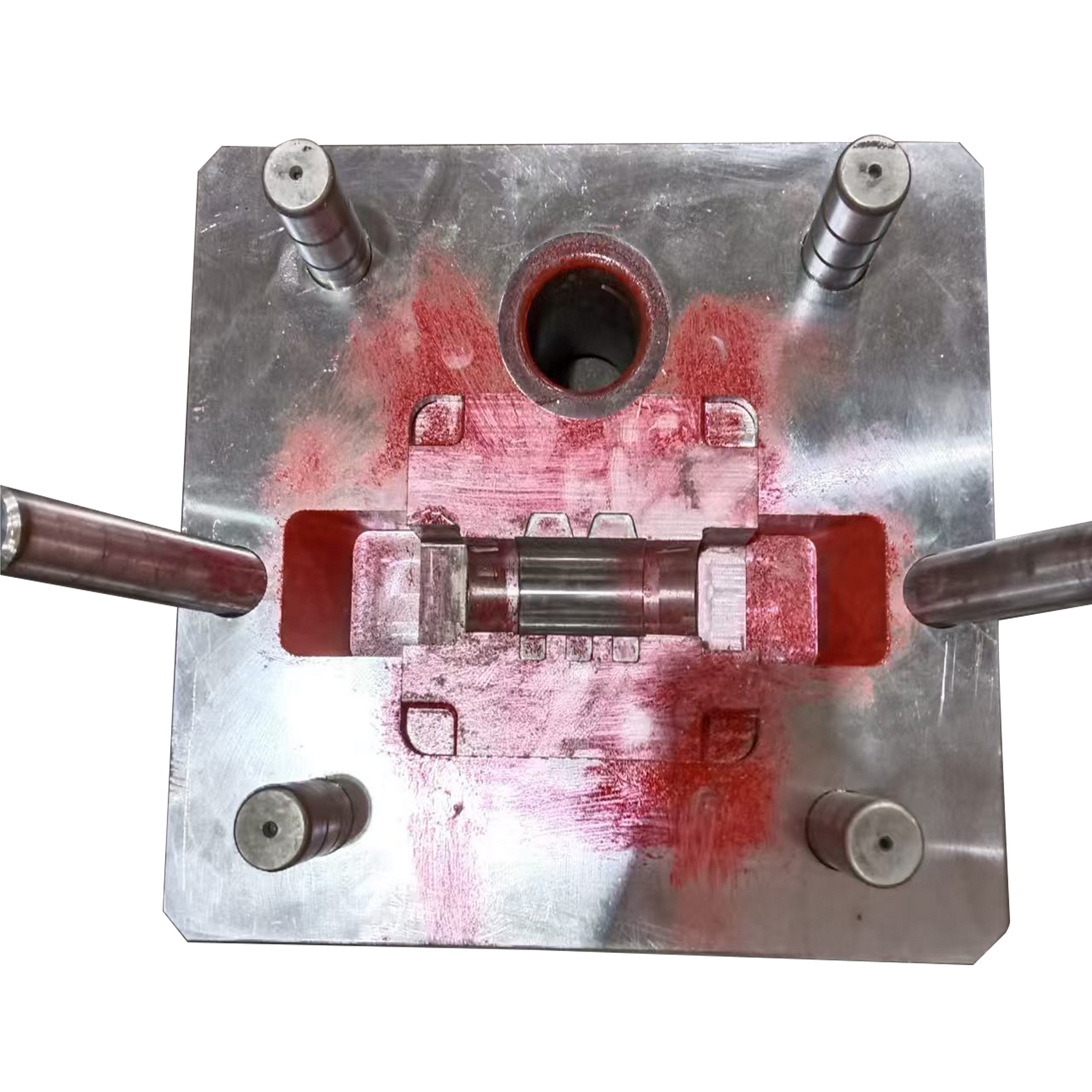

Custom molds play a crucial role in manufacturing processes across various industries, providing the foundation for producing high-quality components with efficiency and precision. At Haoda (Ningbo) Import and Export Co., Ltd, we specialize in creating custom molds tailored to your specific needs. Our advanced equipment, including automatic melting and die-casting machines, allows us to produce molds that not only meet but exceed industry standards.

With a focus on aluminum, zinc, and magnesium alloy products, we leverage our expertise to ensure that each mold is designed and manufactured with the utmost attention to detail. We understand that the success of your project relies heavily on the quality of the molds used, which is why we adhere to strict quality control processes throughout production. Our experienced staff is dedicated to ensuring that your custom mold solutions are delivered on time and within budget, allowing you to focus on your core business operations.

In addition to our technical capabilities, we pride ourselves on our customer-centric approach. Our team is always available to discuss your requirements, answer your questions, and provide guidance throughout the customization process. We believe that effective communication and collaboration are key to achieving mutual success, and we are committed to building lasting relationships with our clients.