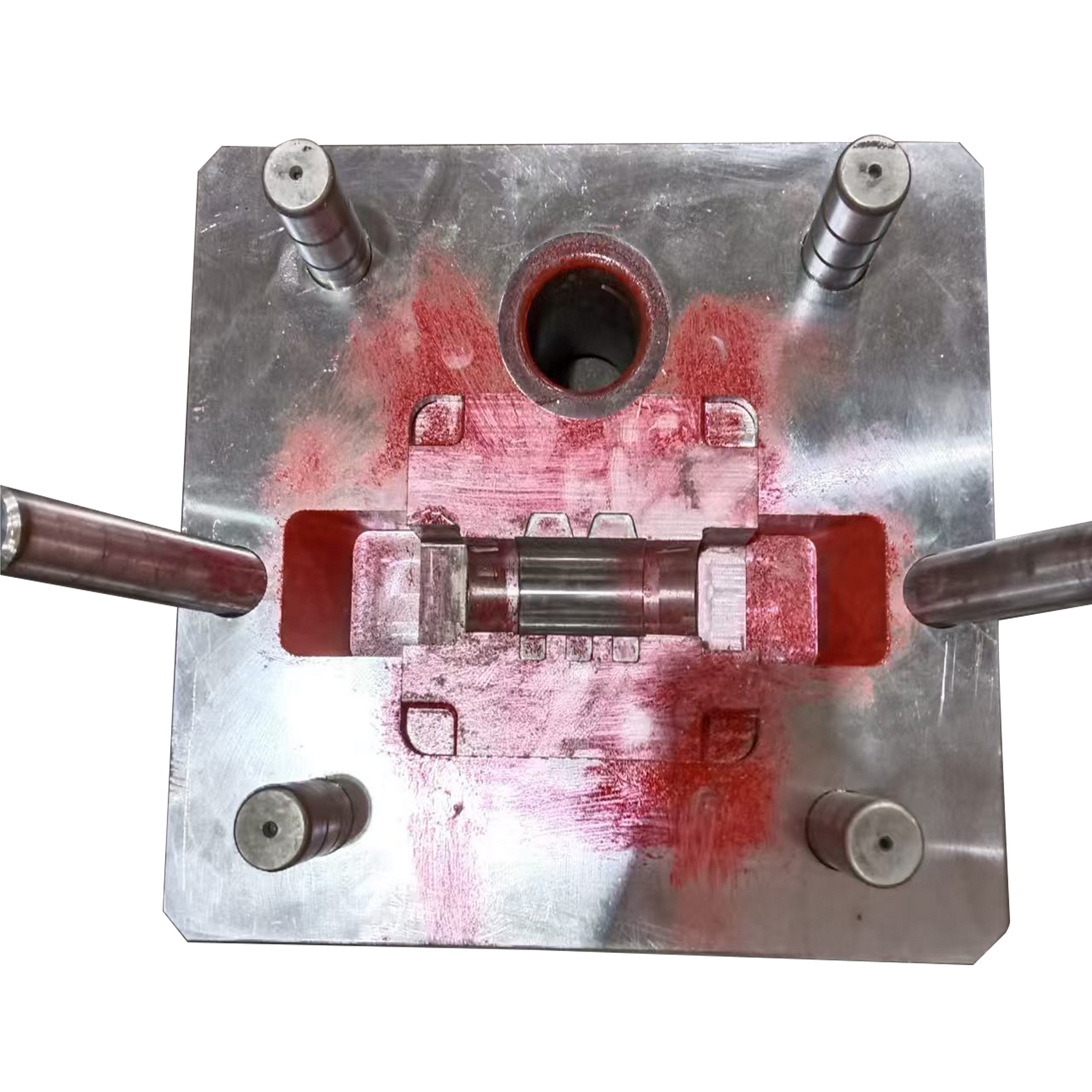

Custom fishing lure molds are essential tools for anglers looking to create their own lures tailored to specific fishing conditions and species. At Haoda (Ningbo) Import and Export Co., Ltd, we specialize in manufacturing high-quality molds that allow you to produce lures with precision and creativity. Our molds are designed to accommodate a variety of lure types, including soft plastics, hard baits, and jigs, ensuring that you have the versatility needed for different fishing scenarios. With our advanced technology and expertise, we provide molds that not only meet your specifications but also enhance the performance of your fishing lures. The customization process is made easy with our dedicated team, who will guide you through every step, from design to production. Whether you are looking to create lures for personal use or for commercial purposes, our custom fishing lure molds offer the durability and quality you need to succeed in the competitive fishing industry.