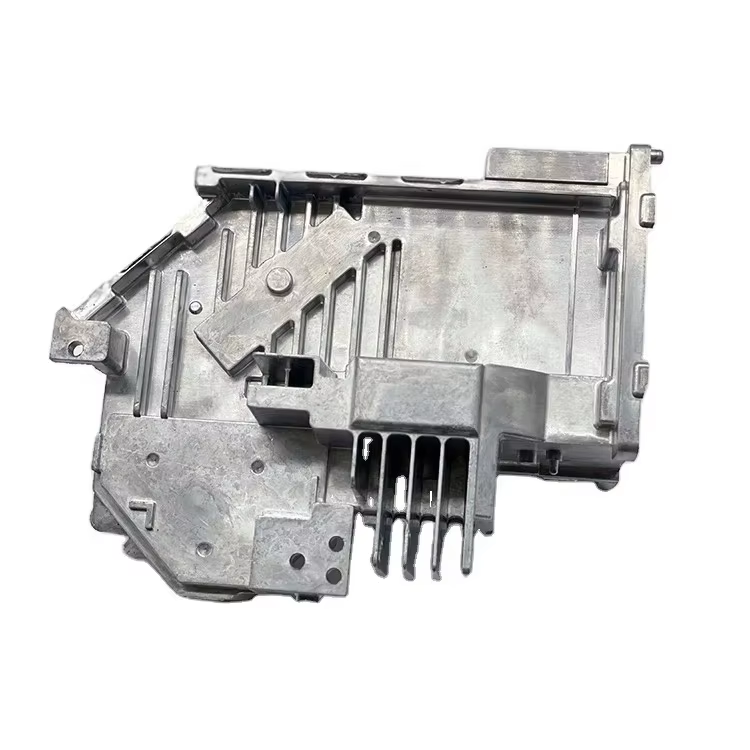

Gravity die casting is a highly efficient manufacturing process that involves pouring molten metal into a reusable mold. This technique is particularly advantageous for producing high-quality, intricate shapes with excellent surface finishes. At Haoda, we specialize in gravity die casting of aluminum, zinc, and magnesium alloys, which are widely used in various industries, including automotive, aerospace, and electronics. Our state-of-the-art equipment ensures that each casting is produced with high precision and minimal defects. Moreover, our commitment to quality is underscored by our IATF16949 certification, which reflects our dedication to maintaining international quality standards. The gravity die casting process allows for rapid production cycles, making it ideal for both small and large batch manufacturing. As we focus on customization, we can accommodate diverse client specifications, ensuring that each product meets the unique demands of our customers. With our experienced team and advanced technology, we guarantee timely delivery and full customer satisfaction, making us your preferred partner for gravity die casting solutions.