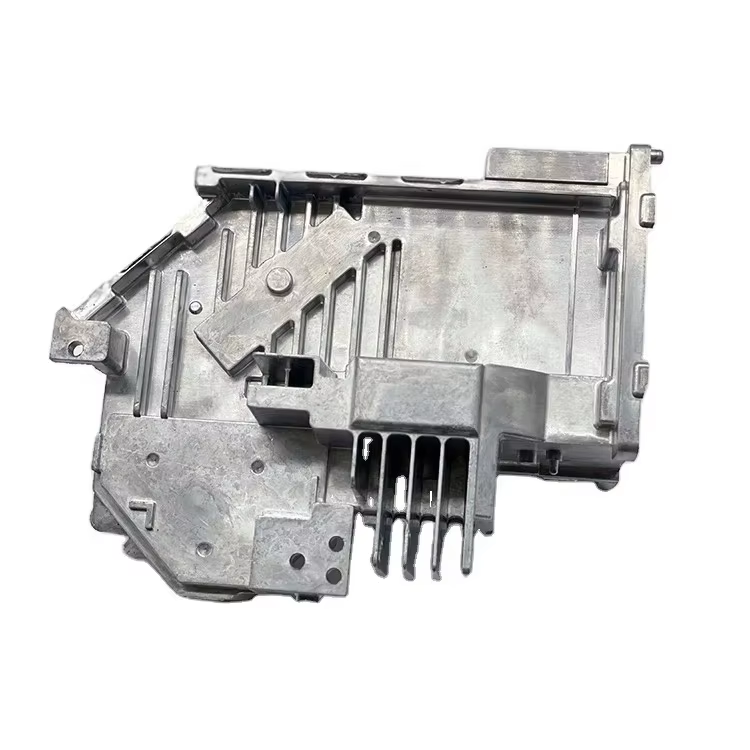

Die casting is a highly efficient manufacturing process that allows for the production of complex shapes with excellent surface finish and dimensional accuracy. At Haoda (Ningbo) Import and Export Co., Ltd, we specialize in die casting aluminum, zinc, and magnesium alloys, which are widely recognized for their lightweight properties and high strength-to-weight ratios. The die casting process involves forcing molten metal into a mold under high pressure, which solidifies to form a precise and durable part. This method not only minimizes material waste but also enables high-volume production at a lower cost, making it an ideal choice for various applications, including automotive, electronics, and consumer goods. Our advanced die casting machines ensure that we can meet the diverse needs of our global clientele, providing products that are not only functional but also aesthetically pleasing. With our focus on innovation and quality, we are committed to delivering die casting solutions that enhance your products and drive your business success.