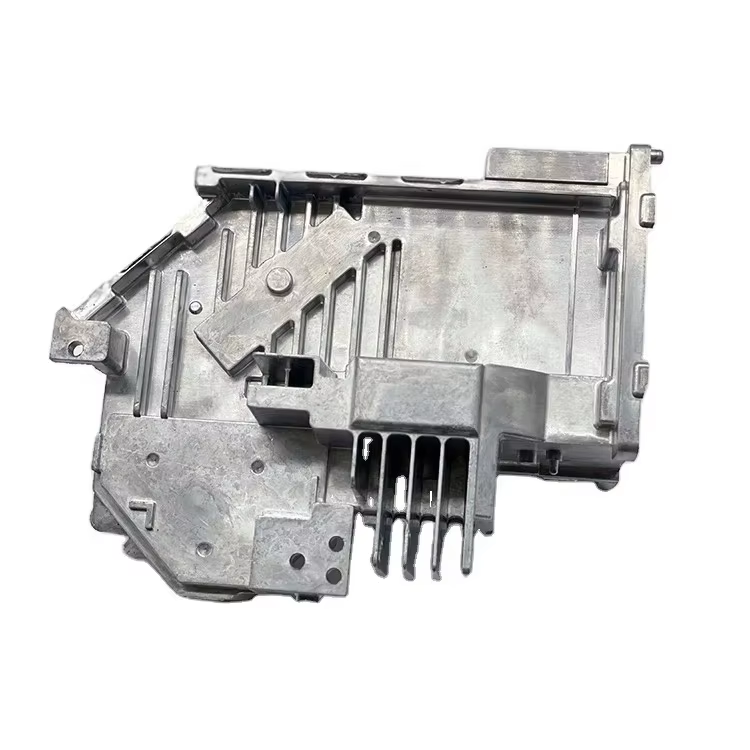

Die casting is a highly efficient manufacturing process that allows for the production of complex shapes with high dimensional accuracy and excellent surface finish. At Haoda (Ningbo) Import and Export Co., Ltd, we specialize in die casting for aluminum, zinc, and magnesium alloys, each of which has its unique advantages. Aluminum die casting is known for its lightweight and corrosion resistance, making it ideal for automotive and aerospace applications. Zinc die casting offers excellent precision and a smooth finish, suitable for intricate designs in electronics and consumer goods. Magnesium die casting is the lightest of the three, providing strength and rigidity for applications where weight reduction is critical. Our state-of-the-art facilities enable us to handle various production volumes, from prototyping to large-scale manufacturing, ensuring that we can meet the diverse needs of our international clients. With a strong focus on quality and customer satisfaction, we utilize advanced technologies and skilled craftsmanship to deliver products that exceed expectations.