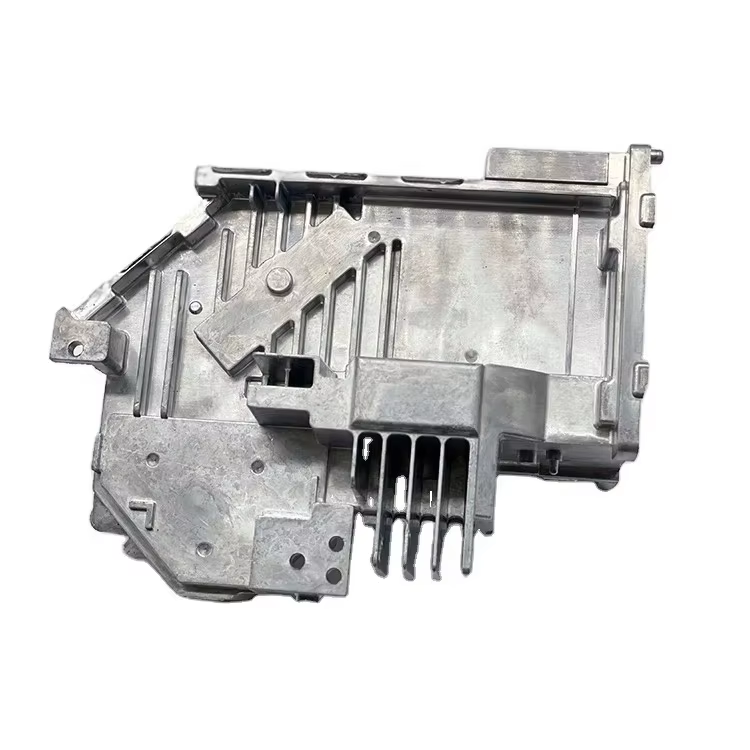

In the competitive landscape of die casting companies, Haoda (Ningbo) Import and Export Co., Ltd stands out as a leader in the customization of aluminum, zinc, and magnesium alloy products. Our advanced manufacturing capabilities are supported by professional equipment such as automatic melting and die-casting machines, CNC machines, and tapping machines, all designed to produce high-precision components. The integration of an X-ray real-time imaging detection system allows us to maintain rigorous quality control, ensuring that every product meets international standards.

Our IATF16949 certification reflects our commitment to quality and customer satisfaction. We understand that each client’s needs are unique; therefore, we offer tailored solutions that not only meet but exceed expectations. Our experienced staff is dedicated to providing thoughtful customer service, making the process seamless from start to finish. We invite you to partner with us to leverage our expertise and innovative solutions for your die casting requirements.