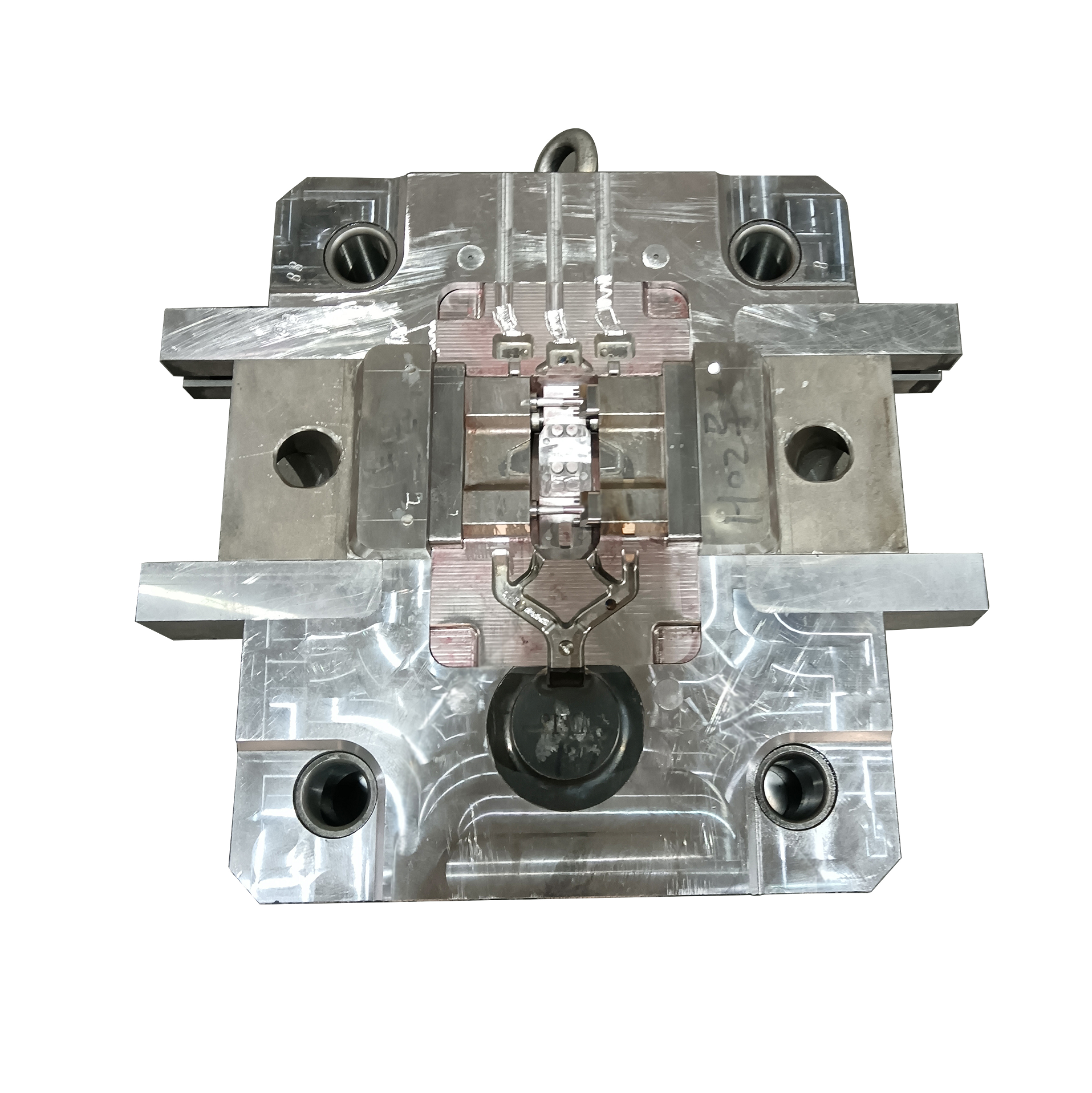

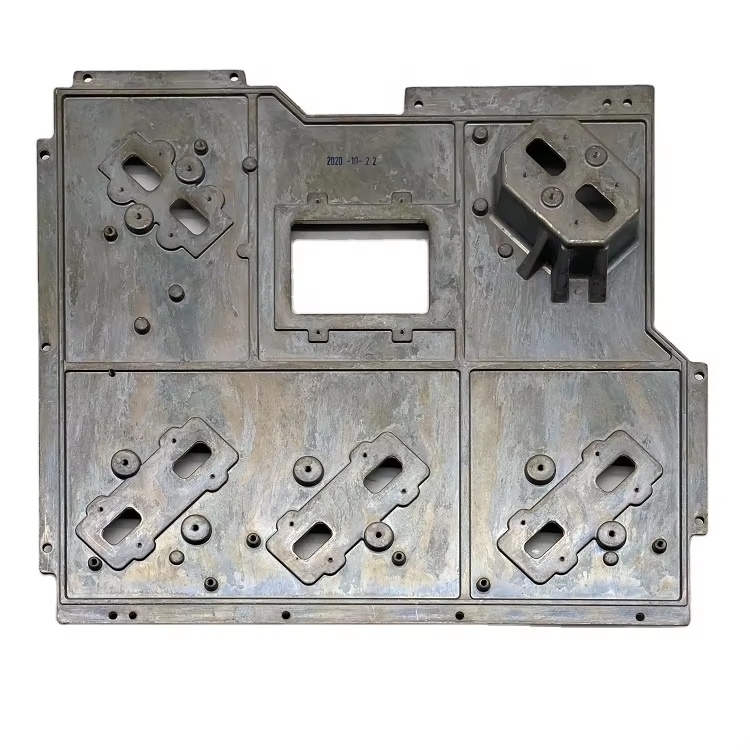

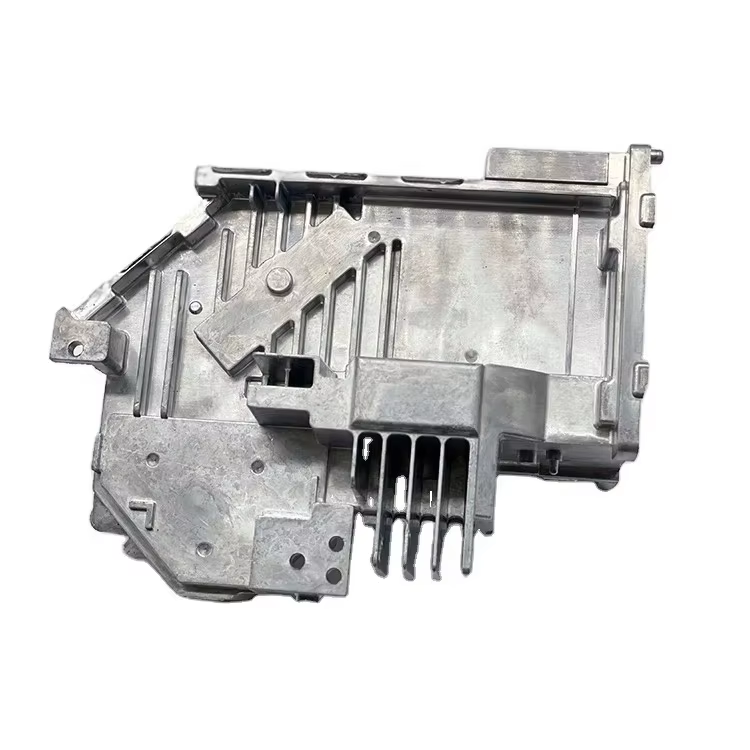

Die casting is a manufacturing process that involves forcing molten metal into a mold cavity under high pressure. At Haoda (Ningbo) Import and Export Co., Ltd., we specialize in producing top-tier die casting products using aluminum, zinc, and magnesium alloys. Our advanced die-casting machines allow us to create complex shapes with tight tolerances, making our products ideal for various applications, including automotive, electronics, and consumer goods.

Aluminum die casting is favored for its lightweight and corrosion-resistant properties, making it suitable for components that require strength without added weight. Zinc die casting offers excellent dimensional accuracy and surface finish, ideal for intricate designs. Magnesium die casting is known for its high strength-to-weight ratio, making it perfect for lightweight applications.

Our commitment to quality is underscored by our IATF16949 certification, which ensures that our manufacturing processes meet the highest industry standards. We utilize state-of-the-art equipment, including CNC machines and tapping machines, to achieve precision and efficiency in production. Our dedicated team of professionals is committed to providing exceptional customer service, guiding clients through the entire process from design to delivery.

With our die casting products, you can expect superior quality, tailored solutions, and a partnership that prioritizes your success. We are dedicated to meeting the evolving needs of the global market, ensuring that our products not only meet but exceed your expectations.