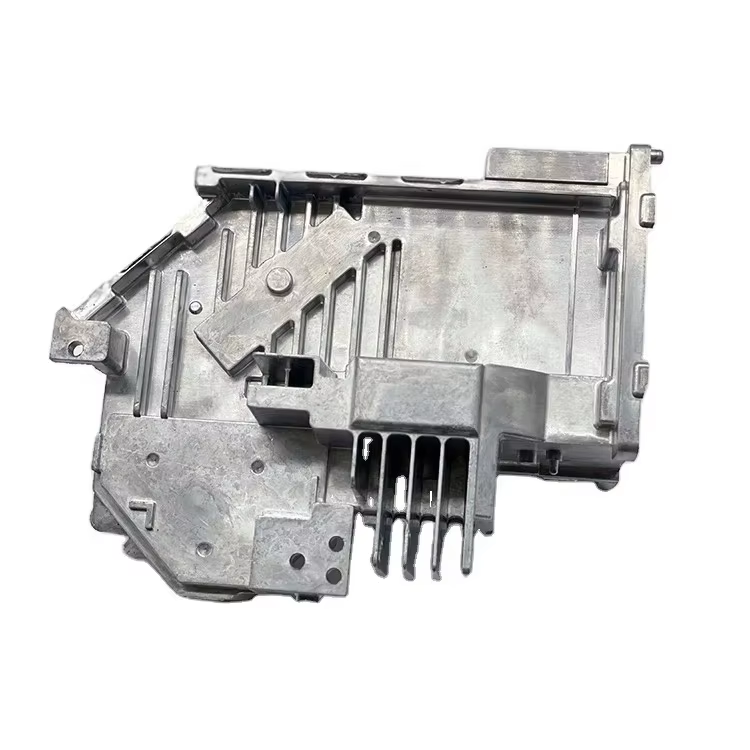

Pressure die casting is a highly efficient manufacturing process used to produce complex metal parts with exceptional accuracy and surface finish. At Haoda (Ningbo) Import and Export Co., Ltd, we leverage advanced technology and skilled craftsmanship to deliver superior pressure die casting solutions. Our automatic melting and die-casting machines enable us to produce high volumes of precision components quickly, making us an ideal choice for industries requiring rapid production without sacrificing quality.

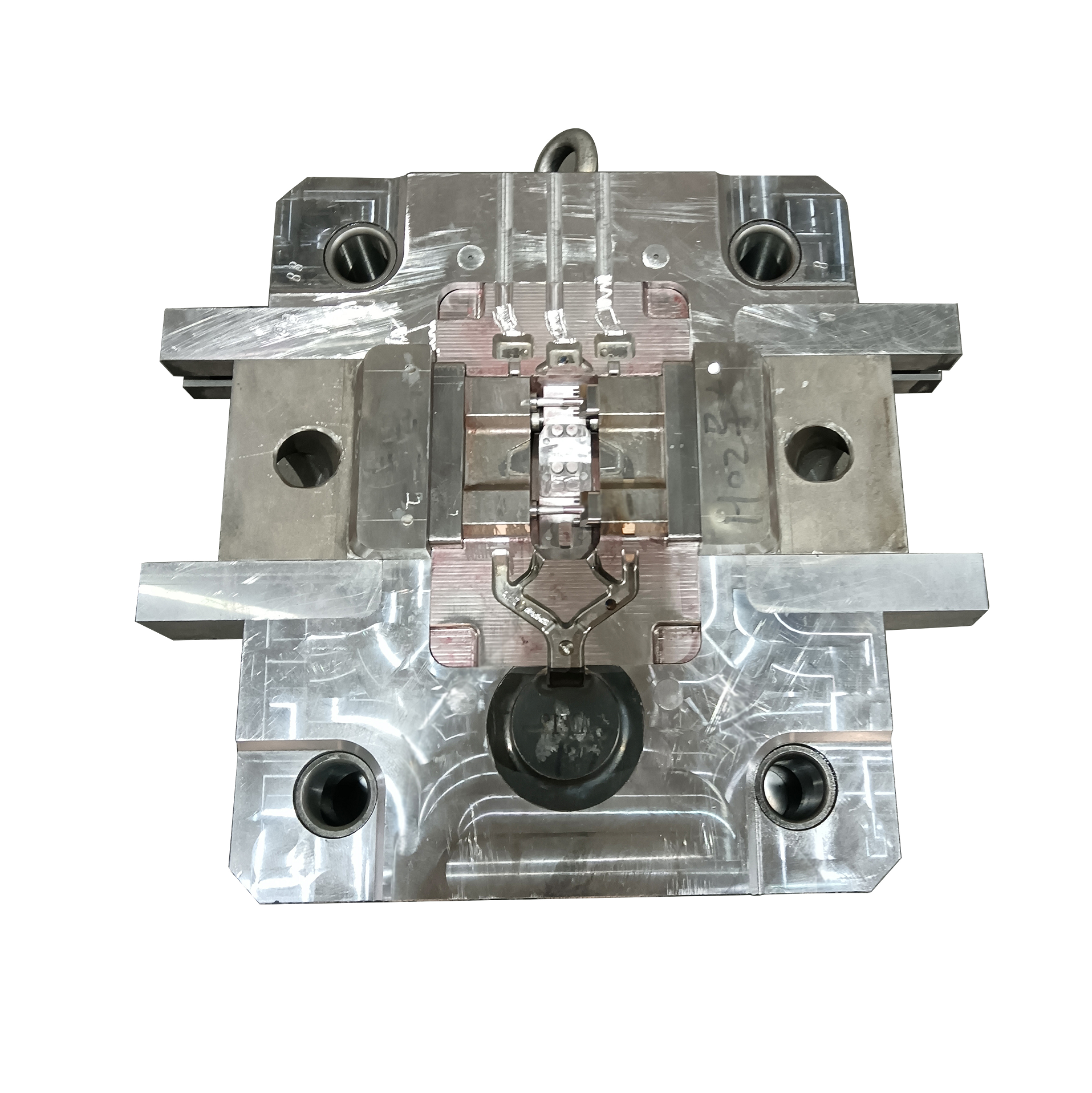

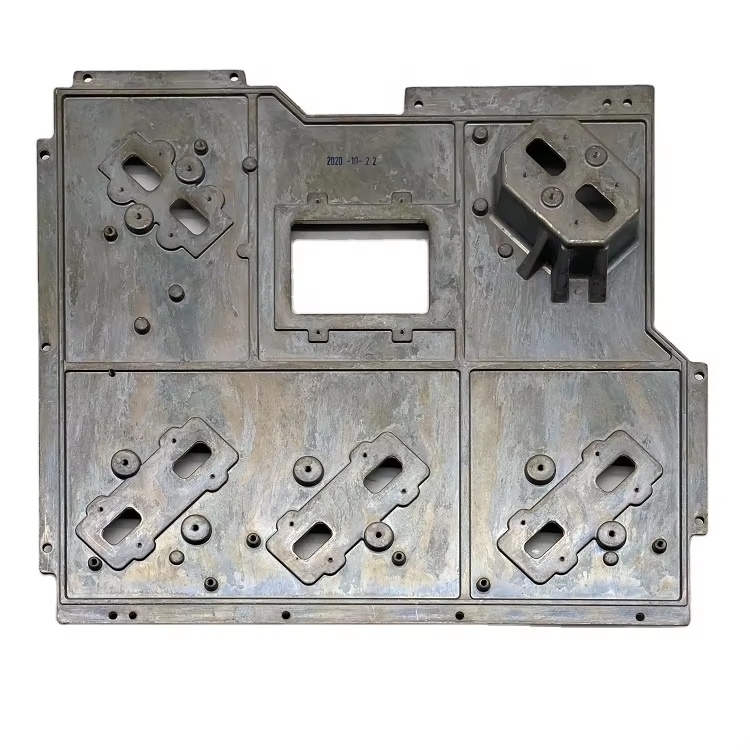

The process begins with molten metal being injected into a mold under high pressure, allowing for intricate designs and tight tolerances. This method is particularly advantageous for producing aluminum, zinc, and magnesium alloy products, as these materials offer excellent strength-to-weight ratios and corrosion resistance. Our commitment to strict quality control ensures that each product undergoes rigorous testing, including CMM inspections and X-ray imaging, to guarantee that it meets your specifications.

Whether you need components for automotive applications, electronic devices, or consumer products, our pressure die casting services can be customized to meet your unique requirements. Our experienced team is dedicated to providing exceptional customer service, guiding you through every step of the process to ensure your satisfaction. Partner with us for reliable, high-quality pressure die casting solutions that drive your success.