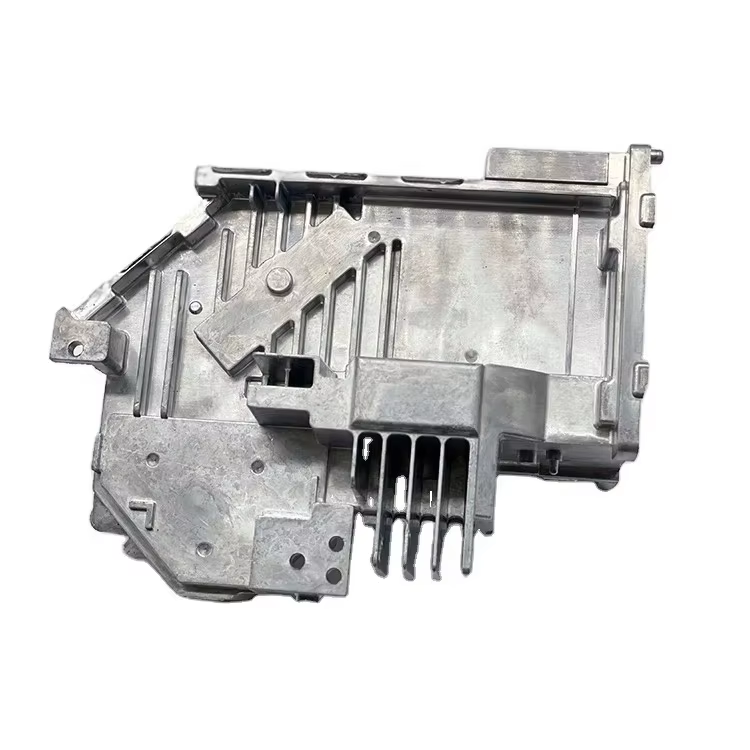

High pressure die casting is a highly efficient manufacturing process that produces intricate metal parts with exceptional dimensional accuracy and surface finish. This method is particularly advantageous for producing high volumes of components, making it ideal for industries such as automotive, aerospace, and consumer electronics. At Haoda (Ningbo) Import and Export Co., Ltd, we utilize cutting-edge technology and equipment to deliver high pressure die casting solutions tailored to your specific needs. Our automatic melting and die-casting machines ensure rapid production rates while maintaining the precision required for complex designs. The use of aluminum, zinc, and magnesium alloys allows us to create lightweight yet robust components that meet the rigorous demands of modern applications. Furthermore, our commitment to quality is reflected in our IATF16949 certification, which guarantees that our products undergo strict quality control processes. We understand the importance of customer satisfaction and strive to exceed expectations with every project. By choosing our high pressure die casting services, you gain a reliable partner dedicated to delivering high-quality, customized solutions that enhance your product offerings and contribute to your business success.