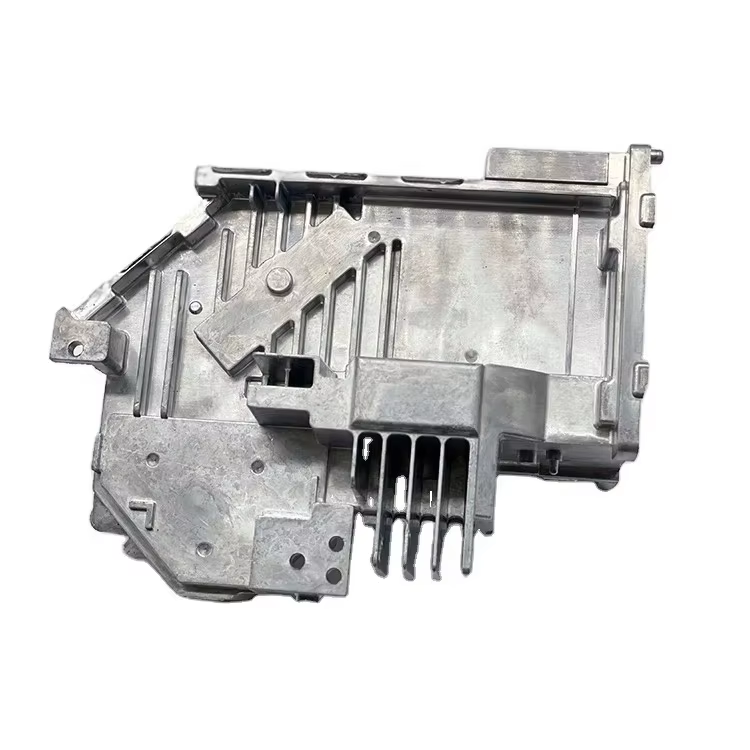

Zinc die casting is a highly efficient manufacturing process that allows for the production of complex shapes with exceptional dimensional accuracy and surface finish. At Haoda (Ningbo) Import and Export Co., Ltd, we specialize in creating custom zinc die casting solutions tailored to meet the specific needs of various industries, including automotive, electronics, and consumer goods. The advantages of zinc die casting include its ability to produce lightweight yet durable components that are resistant to corrosion and wear. Our state-of-the-art facilities enable us to handle both small and large production runs, ensuring timely delivery without compromising on quality. We utilize high-quality zinc alloys that enhance the strength and longevity of the final products. Additionally, our team of experts is committed to providing comprehensive support throughout the entire process, from initial design to final delivery, ensuring that your project is executed seamlessly and efficiently. With a focus on customer satisfaction, we strive to exceed your expectations and contribute to your success through our reliable zinc die casting solutions.