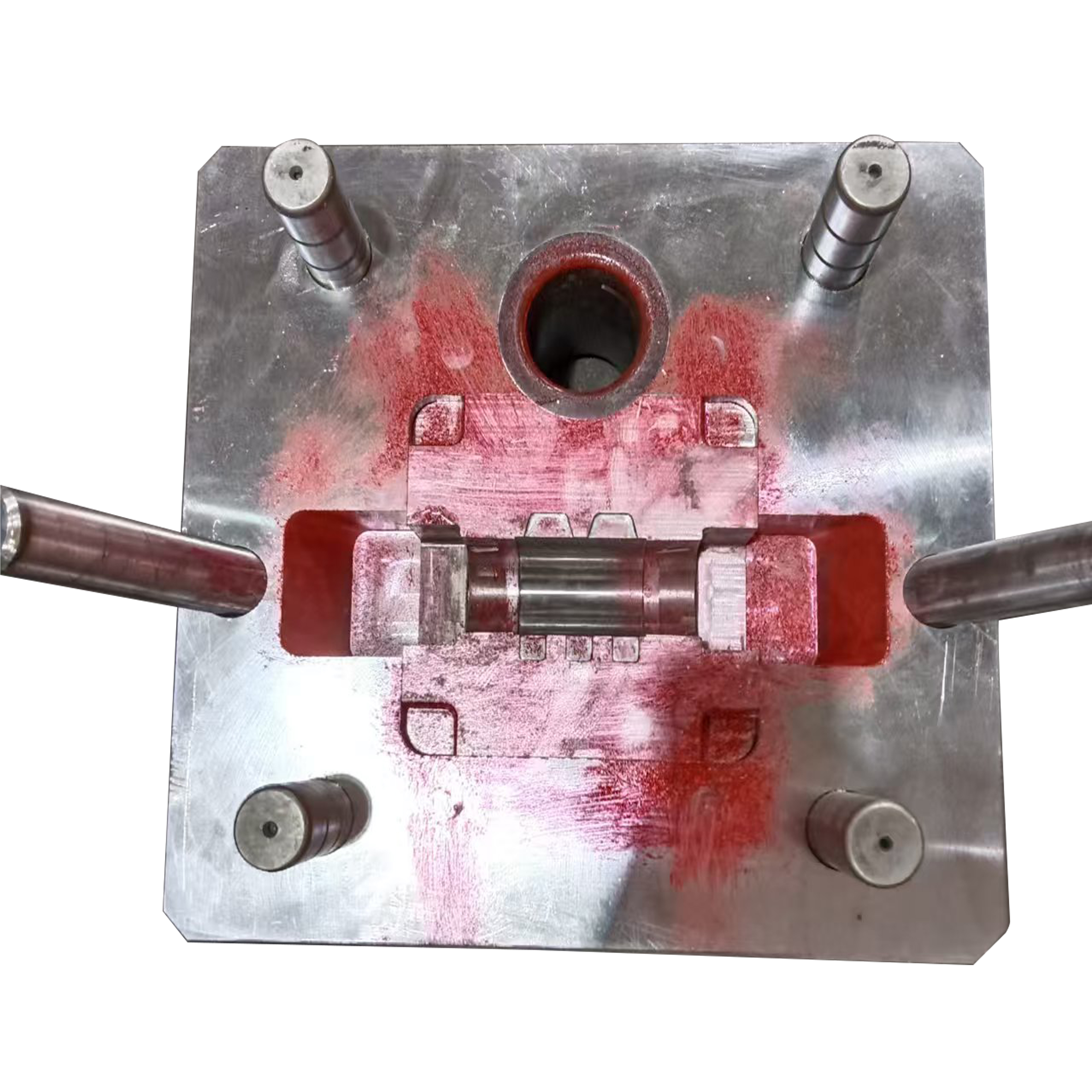

Aluminum T molds are essential components in various manufacturing processes, providing the necessary framework for creating high-quality products. At Haoda (Ningbo) Import and Export Co., Ltd, we specialize in the production of aluminum T molds that cater to a wide range of industries, including automotive, aerospace, and consumer goods. Our molds are crafted with precision, using advanced die-casting and CNC machining techniques that ensure each piece meets strict quality standards. The benefits of using aluminum T molds are numerous; they offer excellent thermal conductivity, lightweight properties, and resistance to corrosion, making them ideal for high-performance applications. Our commitment to customization means that we can tailor our molds to your specific needs, ensuring that you receive a product that enhances your manufacturing efficiency. With rigorous quality control measures in place, including IATF16949 certifications, you can trust that our aluminum T molds will deliver the durability and precision required for your projects. Partner with us for your aluminum T mold needs and experience the difference in quality and service that sets us apart in the industry.