Aluminum concrete molds are essential tools in the construction industry, providing a reliable and efficient way to create concrete structures. At Haoda (Ningbo) Import and Export Co., Ltd, we specialize in manufacturing high-quality aluminum concrete molds that cater to various applications, from residential buildings to large-scale commercial projects. Our molds are designed to withstand the rigors of concrete pouring, ensuring that the final product maintains its shape and integrity.

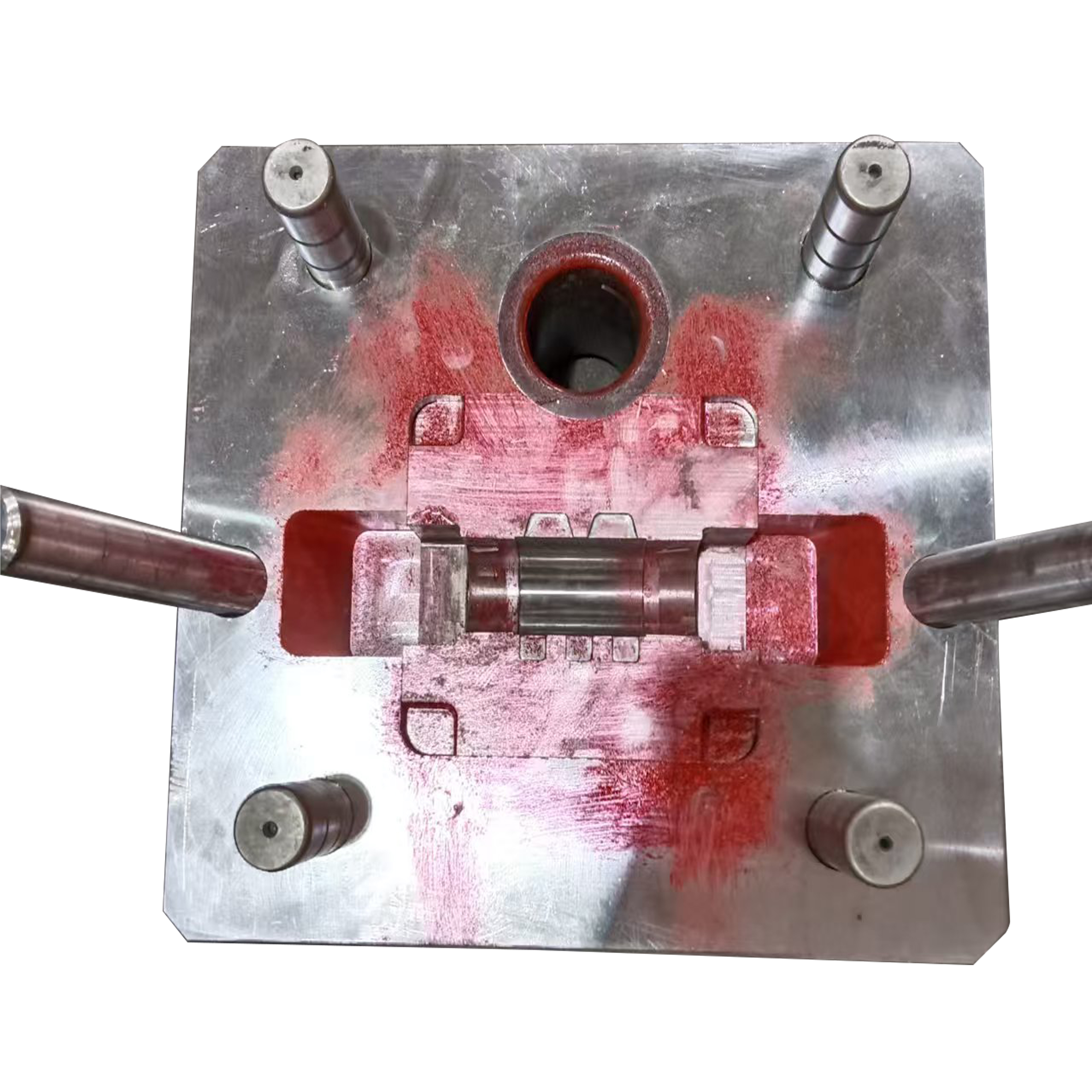

The use of aluminum in mold production offers several advantages over traditional materials. Aluminum is lightweight yet incredibly strong, making it easier to handle while providing the durability needed for repeated use. Our molds are precision-engineered to deliver exact dimensions, ensuring that each concrete piece fits perfectly in its intended application. This precision minimizes waste and maximizes efficiency on job sites, which is critical for meeting project deadlines and budgets.

Moreover, our commitment to customization means that we can design molds that meet your specific needs. Whether you require unique shapes, sizes, or features, our team is dedicated to delivering solutions that enhance your construction projects. With a focus on customer satisfaction, we work closely with you throughout the design and manufacturing process to ensure that the final product exceeds your expectations.

In addition to our high-quality molds, we pride ourselves on providing exceptional customer service. Our knowledgeable staff is always available to answer questions, provide support, and ensure that you have the best experience possible. Whether you are a contractor, architect, or manufacturer, our aluminum concrete molds will help you achieve outstanding results in your concrete applications.