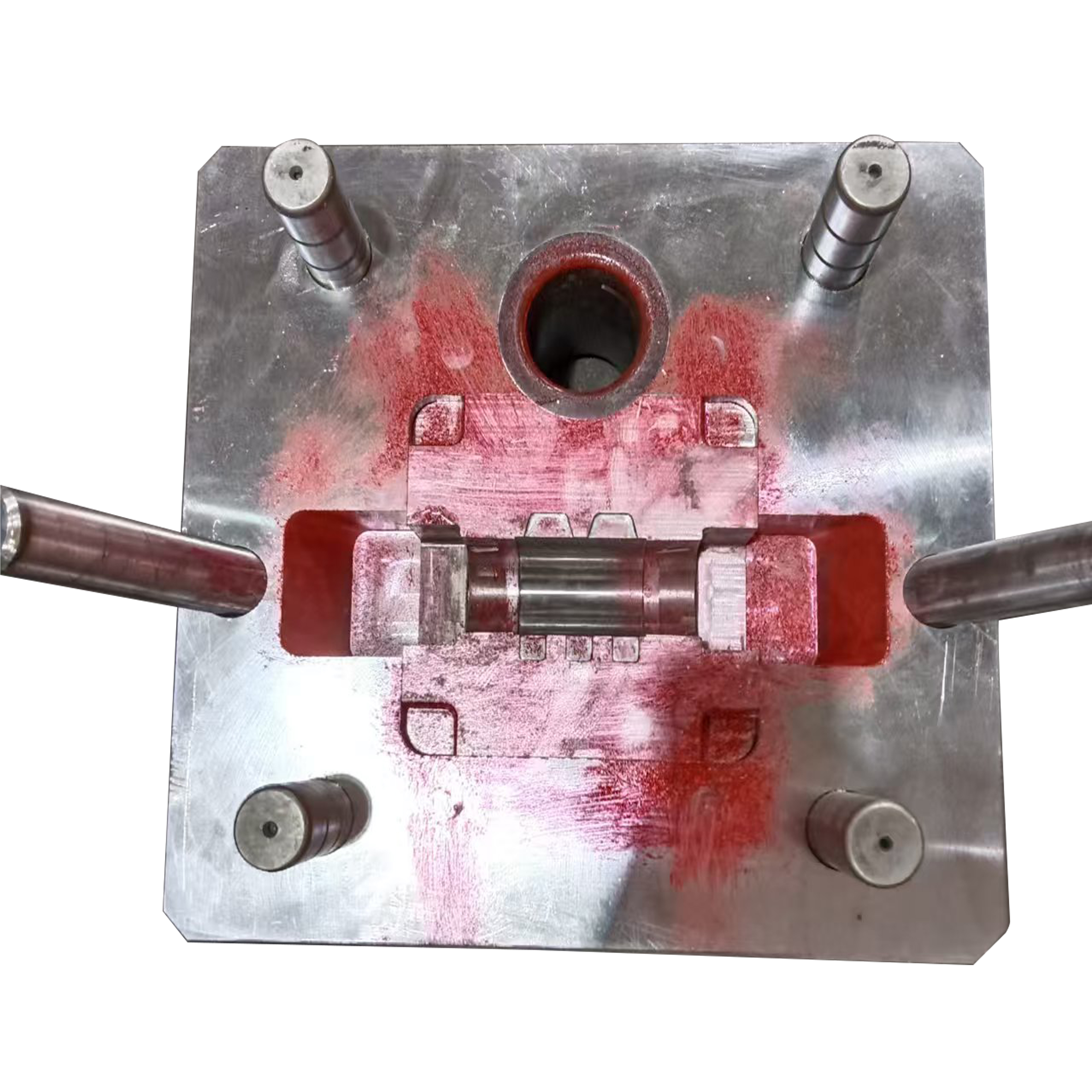

Aluminum ingot molds play a crucial role in the casting process, providing the necessary shape and structure for aluminum products. At Haoda (Ningbo) Import and Export Co., Ltd, we specialize in creating high-quality aluminum ingot molds designed to cater to various industrial applications. Our molds are crafted from premium materials, ensuring longevity and resistance to wear and tear during the casting process. The precision of our molds contributes significantly to the overall quality of the aluminum ingots produced, enabling manufacturers to achieve high levels of accuracy in their products. With our advanced manufacturing capabilities, we can produce molds in various sizes and configurations, making them suitable for different casting requirements. Our commitment to quality control means that each mold undergoes rigorous testing to ensure it meets the highest standards. By choosing our aluminum ingot molds, you are investing in products that enhance your operational efficiency and product quality, ultimately leading to greater customer satisfaction.