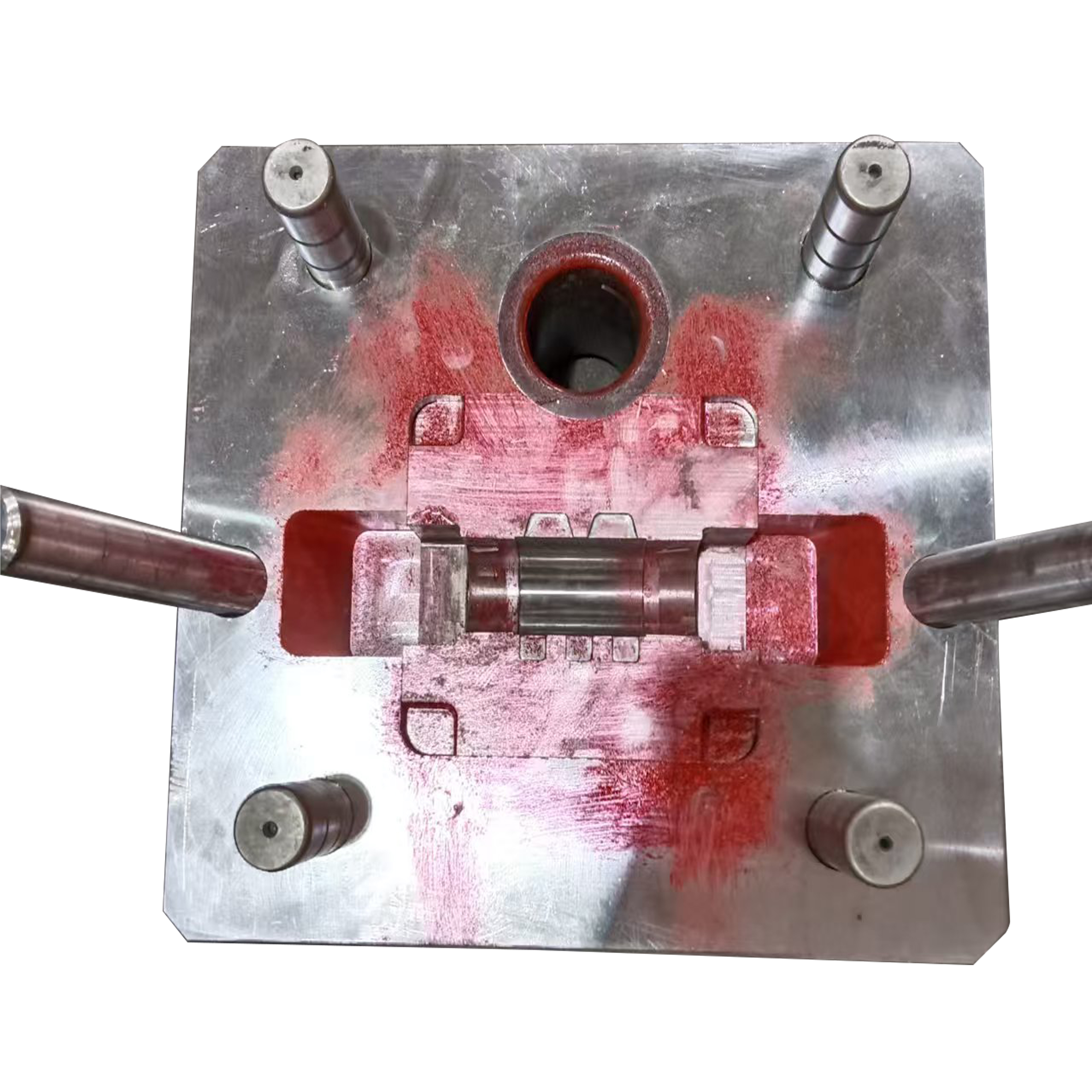

Aluminium die casting moulds are essential components in various industries, providing the foundation for creating high-quality, precision-engineered parts. At Haoda (Ningbo) Import and Export Co., Ltd, we specialize in the design and manufacturing of these moulds, ensuring that they meet the diverse needs of our global clientele. Our aluminium die casting process involves pouring molten aluminium into a mould cavity under high pressure, which allows for the production of intricate shapes and designs with excellent surface finish and dimensional accuracy. This method is particularly advantageous for mass production, as it enables rapid cycle times and reduces material waste.

Our team of skilled professionals is dedicated to understanding the specific requirements of each project, ensuring that our aluminium die casting moulds are tailored to meet your exact specifications. We utilize advanced technologies, such as CNC machining and real-time imaging detection systems, to enhance the quality and precision of our moulds. Furthermore, our commitment to continuous improvement and innovation means that we are always exploring new techniques and materials to enhance our offerings. Whether you require moulds for automotive, aerospace, or consumer products, our aluminium die casting solutions are designed to deliver exceptional performance and reliability, helping you achieve your production goals with ease.