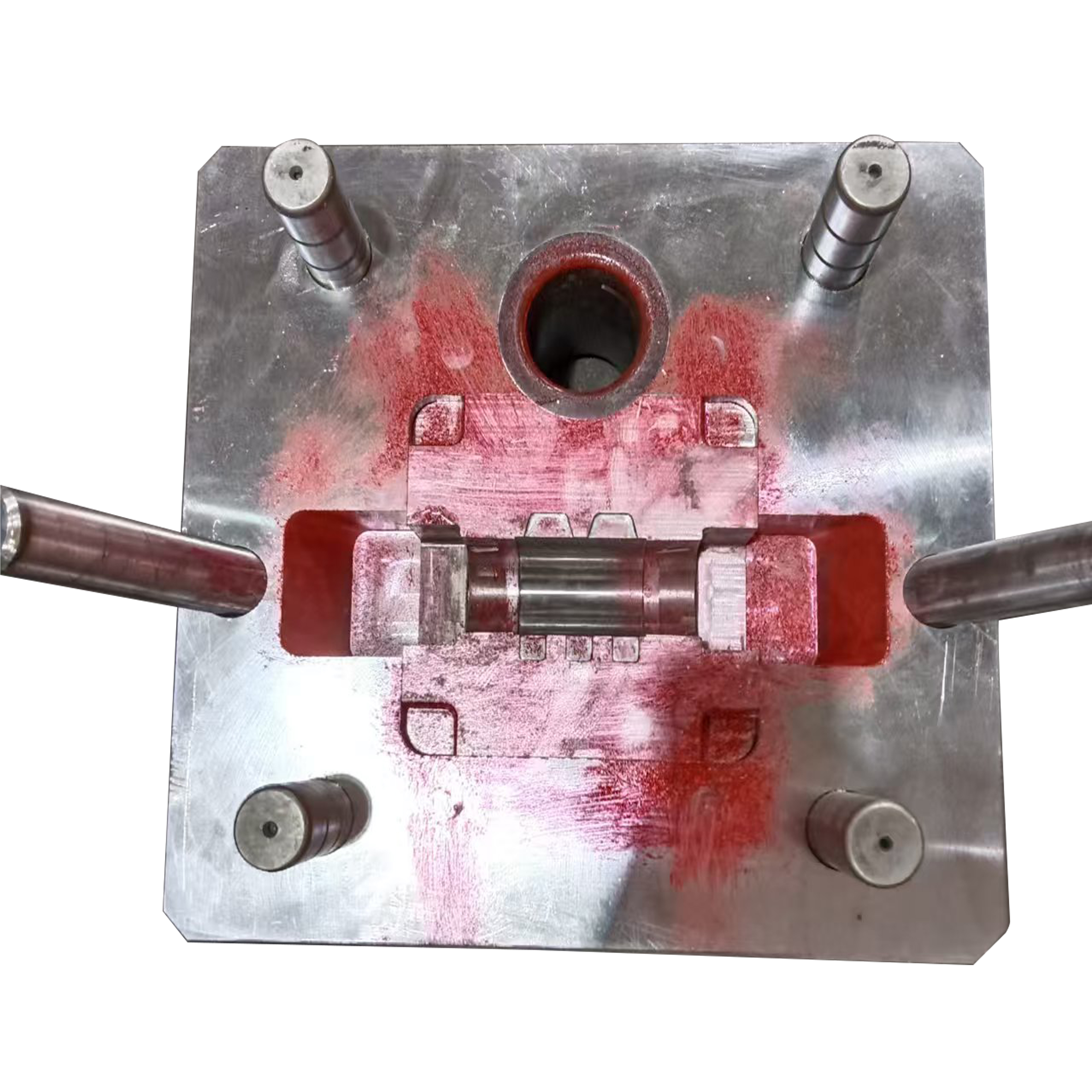

Aluminum molds are essential components in various manufacturing processes, particularly in industries such as automotive, consumer electronics, and medical devices. Their lightweight nature, combined with excellent thermal conductivity and corrosion resistance, makes aluminum an ideal material for mold production. At Haoda (Ningbo) Import and Export Co., Ltd, we specialize in creating customized aluminum molds that cater to diverse production needs. Our molds are designed to facilitate efficient casting processes, ensuring that your products are manufactured quickly and accurately. Our advanced production techniques, including CNC machining and die-casting, allow us to produce molds with intricate designs and complex features. This capability is crucial for industries that demand high precision and quality, where even the slightest deviation can impact product performance. Additionally, our commitment to quality is demonstrated through our IATF16949 certification, which guarantees that our manufacturing processes meet the highest standards. By choosing our aluminum molds, you not only benefit from superior quality but also gain a reliable partner dedicated to supporting your business needs. Our experienced team is always available to discuss your specific requirements, ensuring that you receive the best solutions tailored to your production goals.