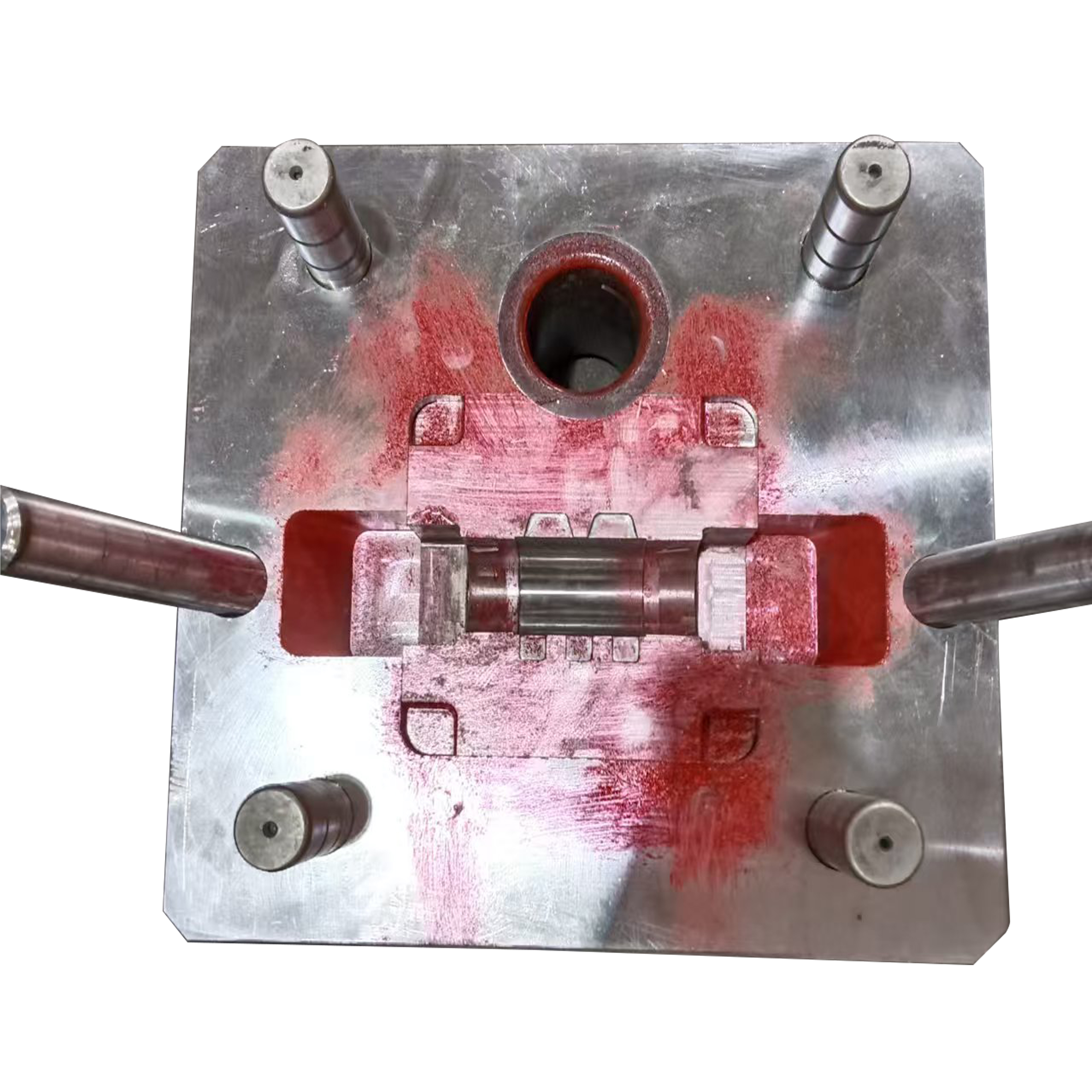

Aluminium die casting molds are crucial in the manufacturing sector, particularly for producing complex shapes and components with high precision. At Haoda (Ningbo) Import and Export Co., Ltd, we specialize in delivering top-notch aluminium die casting molds that cater to various industries, including automotive, electronics, and consumer goods. Our molds are designed to withstand high pressures and temperatures, ensuring that they can handle the rigors of the die casting process while producing consistent, high-quality parts.

Our advanced CNC machining capabilities allow us to create intricate designs with tight tolerances, which are essential for modern manufacturing. The use of high-grade aluminium alloys in our molds not only enhances durability but also improves the overall performance of your production line. With our focus on customization, we can adapt our molds to meet the specific needs of your products, ensuring optimal performance and efficiency.

Moreover, our commitment to quality control means that every mold undergoes rigorous testing and inspection before it reaches you. We utilize advanced detection systems such as X-ray real-time imaging to ensure that our molds are free from defects and meet all required specifications. This attention to detail guarantees that our customers receive products that not only meet but exceed their expectations, solidifying our reputation as a leader in the aluminium die casting mold industry.