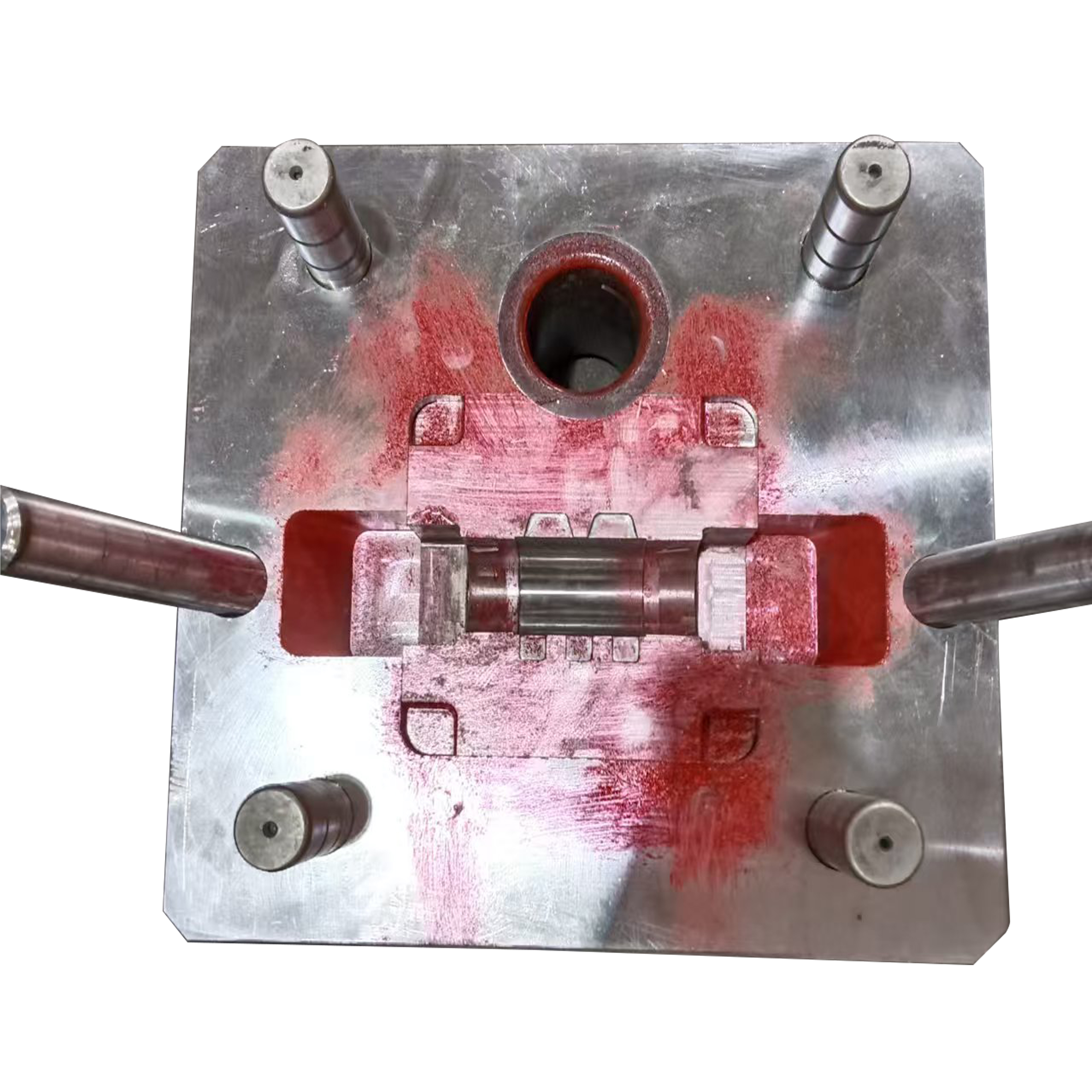

Die cast aluminum molds are essential in the manufacturing process of a variety of industries, including automotive, aerospace, and consumer goods. At Haoda (Ningbo) Import and Export Co., Ltd, we specialize in producing high-quality die cast aluminum molds tailored to meet the specific needs of our clients. Our molds are created using advanced die-casting technology, which allows for the production of complex shapes with high precision and minimal post-processing. The aluminum material used in our molds provides excellent thermal conductivity, ensuring even heat distribution during the casting process. This characteristic is crucial for achieving uniform quality in the final products. Furthermore, our molds are designed to be lightweight yet sturdy, facilitating easier handling and reduced operational costs. With our commitment to quality and customer satisfaction, we ensure that every die cast aluminum mold we produce undergoes rigorous testing and quality assurance measures. This dedication to excellence not only enhances the performance of our molds but also builds long-lasting relationships with our clients. By choosing Haoda, you are investing in a reliable solution that maximizes productivity and efficiency in your manufacturing processes.