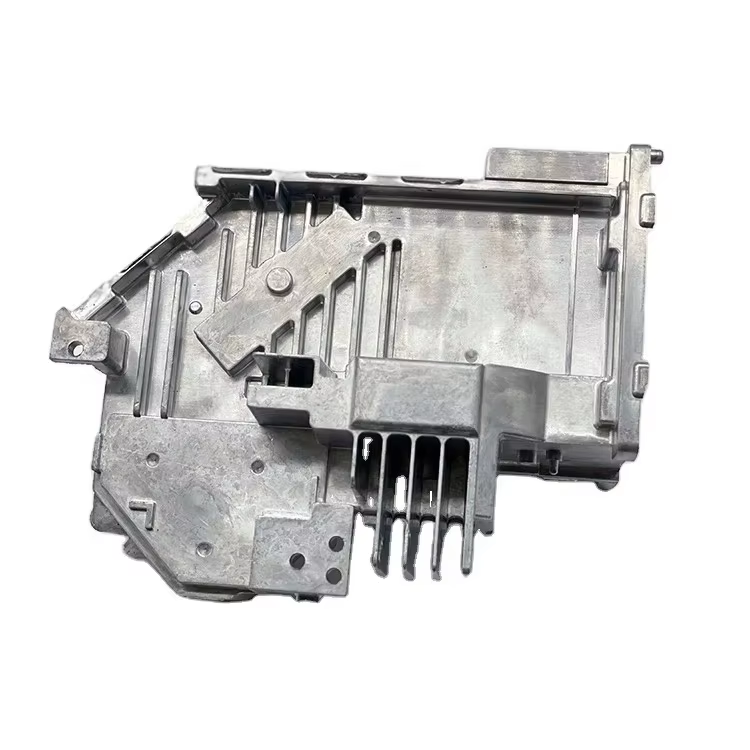

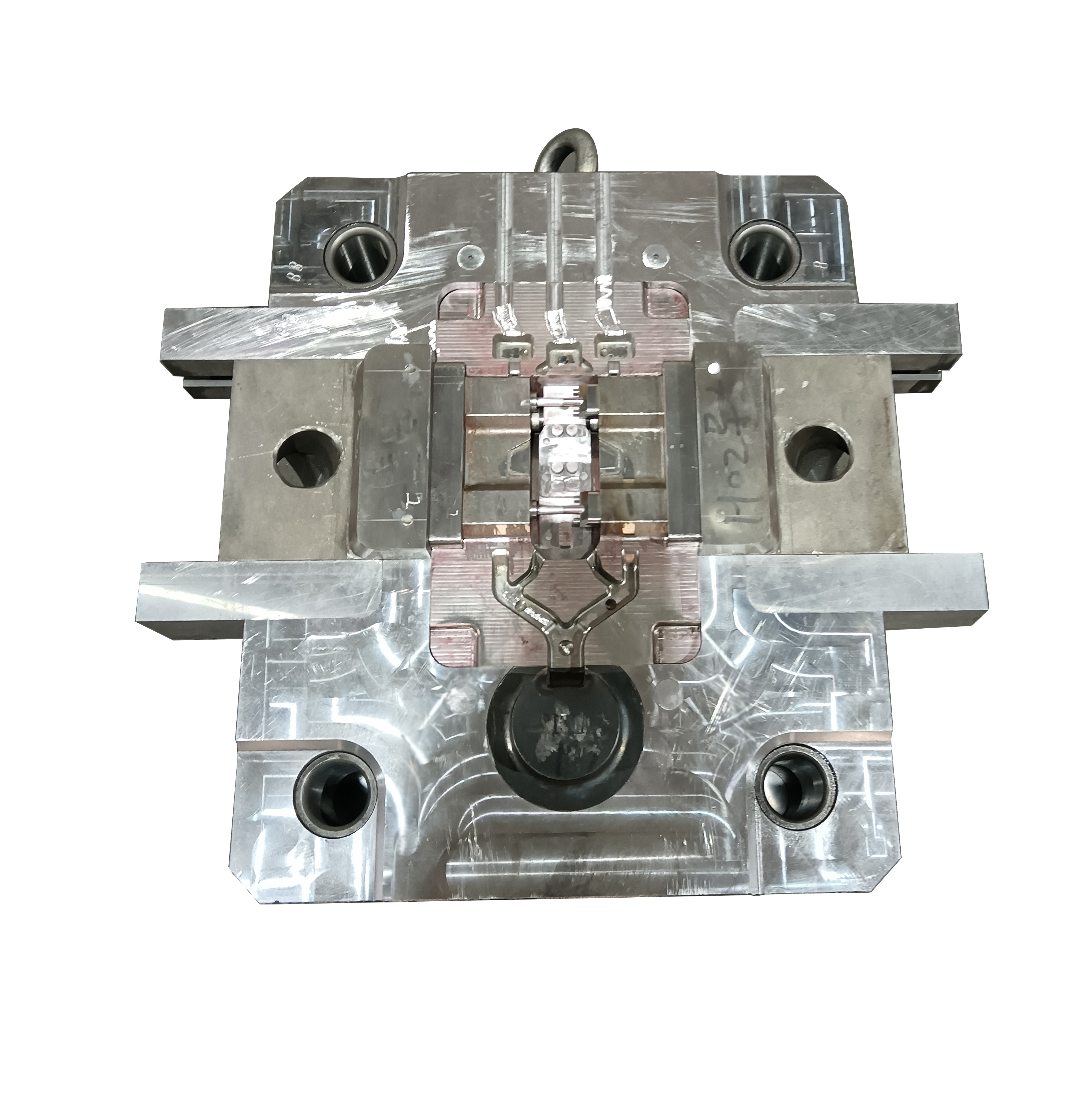

The aluminum die casting process is a highly efficient, precision manufacturing technique that transforms molten aluminum alloy into complex, high-integrity components through the application of high pressure, making it a preferred choice for industries seeking to balance productivity, quality, and cost-effectiveness in high-volume production. Characterized by its speed, repeatability, and ability to produce parts with tight tolerances and excellent surface finishes, the aluminum die casting process involves a series of carefully orchestrated steps that begin with the preparation of raw materials and end with the inspection of finished components. The first stage of the aluminum die casting process involves melting high-purity aluminum alloy—often combined with trace elements like silicon, copper, or magnesium to enhance specific properties such as strength, corrosion resistance, or castability—in automatic melting furnaces that maintain precise temperature control to ensure optimal fluidity. Once molten, the aluminum alloy is injected into a preheated aluminum die casting mould at pressures ranging from 10 to 150 MPa, filling the mould cavity rapidly to capture intricate details and prevent the formation of defects like air pockets or shrinkage. The mould, typically made from heat-resistant tool steel, is designed with cooling channels that accelerate the solidification process, allowing for fast cycle times—often as short as 30 seconds per part—making the aluminum die casting process ideal for mass production. After solidification, the mould is opened, and the finished part is ejected, followed by secondary processes such as trimming, deburring, machining, or surface treatment (including powder coating, anodizing, or plating) to meet specific application requirements. A key advantage of the aluminum die casting process is its ability to produce near-net-shape parts, minimizing the need for expensive post-processing and reducing material waste, which contributes to its cost-effectiveness and sustainability. The precision of the aluminum die casting process is further enhanced by advanced quality control measures, including X-ray real-time imaging detection to identify internal defects, CMM inspections to verify dimensional accuracy, and tensile testing to ensure mechanical properties meet industry standards. These quality checks are integral to the aluminum die casting process, particularly for industries like automotive, aerospace, and medical devices, where component failure can have serious consequences. The aluminum die casting process is also highly versatile, capable of producing parts of varying sizes—from small electronic enclosures to large automotive components—and complexities, including parts with thin walls, internal cavities, and intricate geometries that would be difficult to achieve with other manufacturing methods. Continuous advancements in the aluminum die casting process, such as the integration of computer-aided engineering (CAE) simulations and automated process control systems, have further improved its reliability and efficiency, allowing manufacturers to optimize parameters like injection speed, pressure, and temperature in real time. Adherence to international standards and certifications, such as IATF 16949, ensures that the aluminum die casting process meets the highest quality and safety requirements, making it a trusted choice for global customers seeking consistent, high-performance components. Whether used to produce engine brackets, electronic housings, or consumer goods, the aluminum die casting process remains a cornerstone of modern manufacturing, offering a unique combination of speed, precision, and cost-effectiveness that drives innovation across industries.