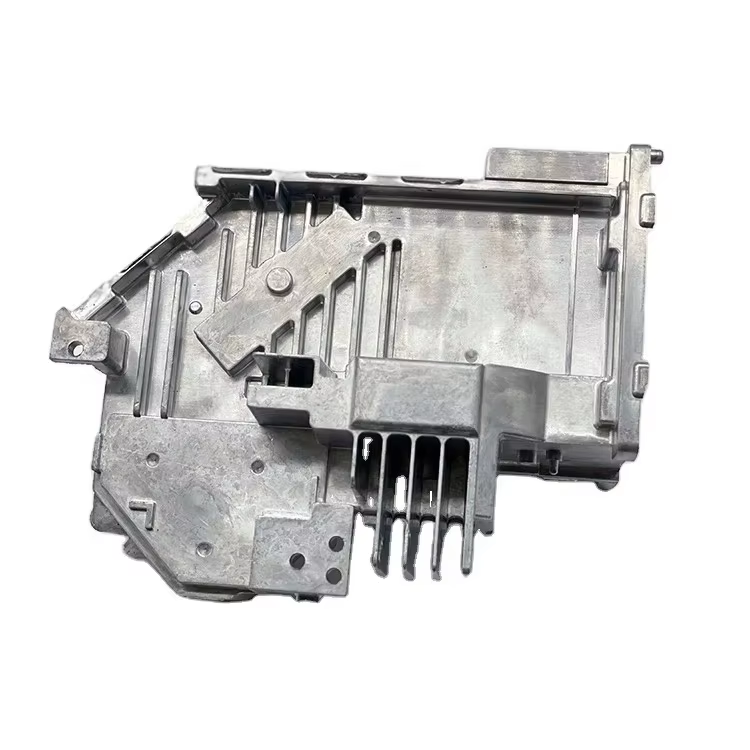

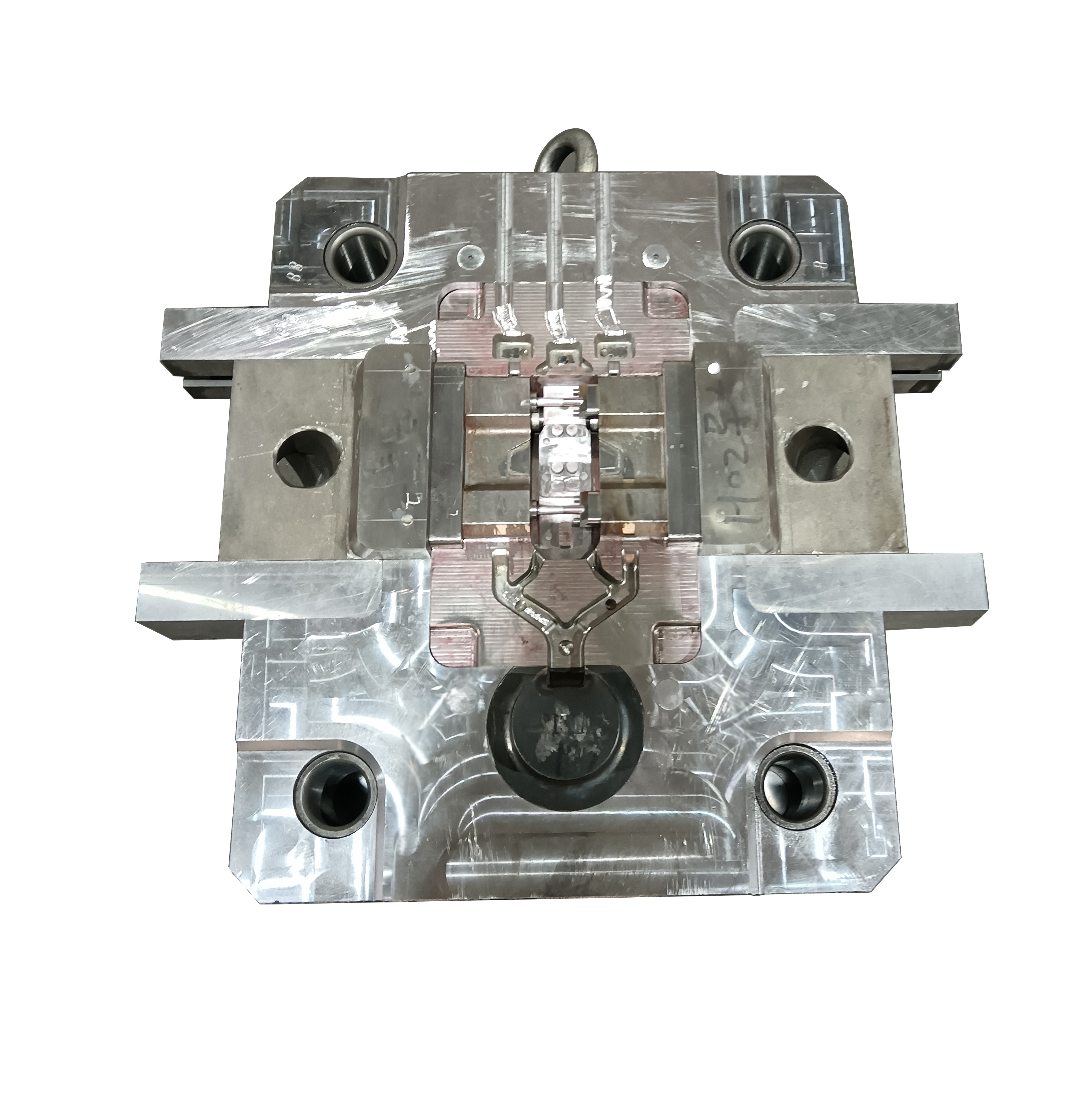

Aluminum die casting is a highly efficient manufacturing process that allows for the production of complex shapes with excellent surface finishes. At Haoda (Ningbo) Import and Export Co., Ltd, we specialize in the customization of aluminum die castings that cater to various industries, including automotive, electronics, and consumer goods. Our advanced die-casting technology enables us to create intricate designs while maintaining dimensional accuracy. The use of aluminum alloys not only enhances the strength and durability of our products but also makes them lightweight, which is crucial for many applications. Our team of experts works closely with clients to understand their specific needs and deliver solutions that meet their exact requirements. With a focus on quality and innovation, we ensure that our aluminum die casting products not only meet but exceed industry standards. Whether you need prototypes or large-scale production runs, we are equipped to handle projects of any size, ensuring timely delivery without compromising quality. Partner with us for your aluminum die casting needs and experience the difference in quality and service.