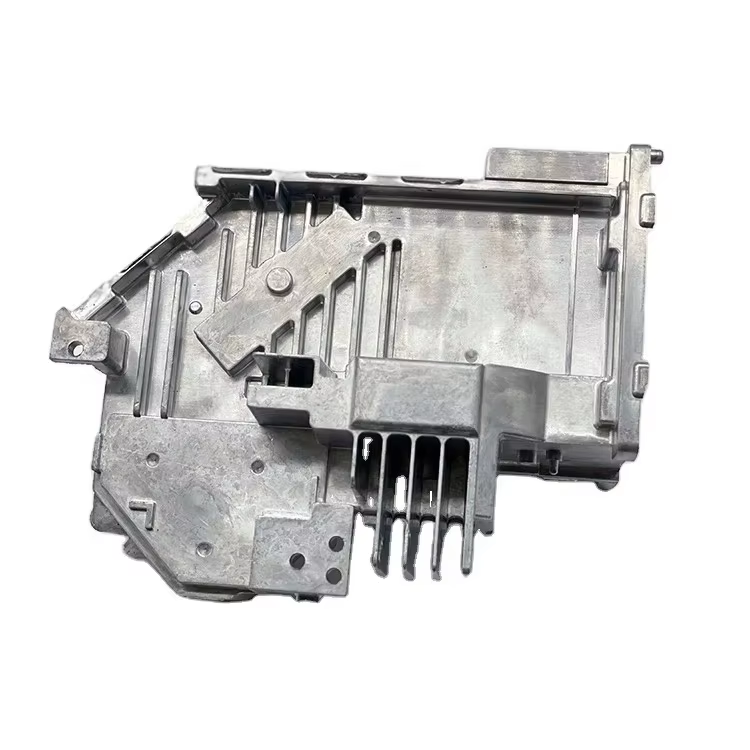

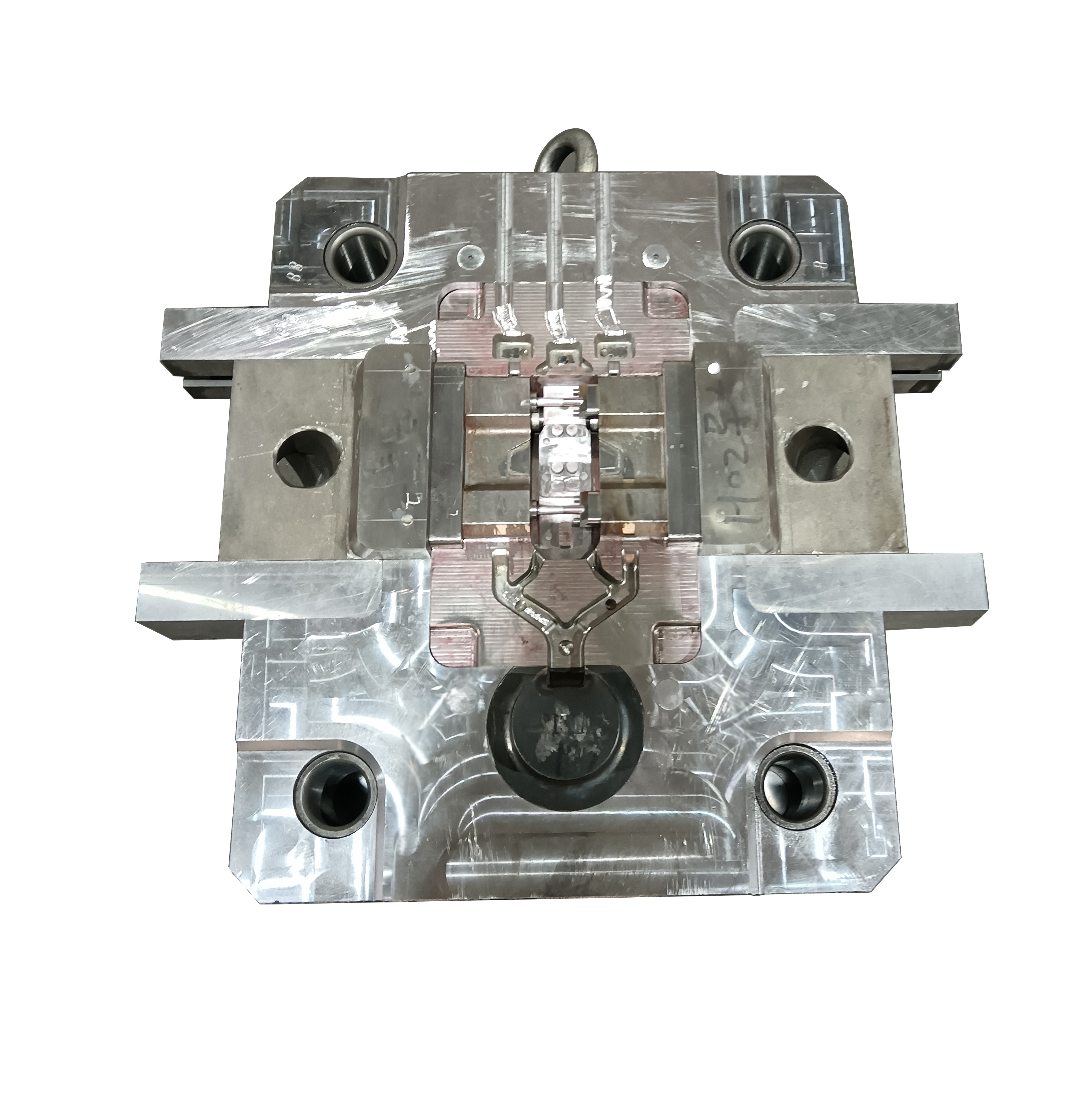

In the realm of precision manufacturing, the aluminum die casting mould stands as a cornerstone component that directly dictates the quality, consistency, and efficiency of aluminum die casting production, serving as the critical interface between raw material and finished product for industries ranging from automotive and electronics to aerospace and consumer goods. Crafted with meticulous attention to detail, an exceptional aluminum die casting mould must withstand extreme temperatures, repeated pressure cycles, and the corrosive nature of molten aluminum while maintaining tight dimensional tolerances and surface integrity to ensure each cast part meets exact specifications. The design and production of an aluminum die casting mould require a deep understanding of material science, thermal dynamics, and machining precision, as factors such as gate placement, cooling channel layout, and cavity geometry directly impact flow dynamics, solidification rates, and the final mechanical properties of the cast component. High-quality aluminum die casting moulds are typically fabricated from premium tool steels or alloy steels, heat-treated to enhance hardness and wear resistance, and finished with precision machining techniques to achieve surface roughness as low as 0.2 microns—critical for reducing friction, preventing material adhesion, and ensuring easy part ejection. What sets superior aluminum die casting moulds apart is their ability to balance durability with design flexibility, accommodating complex part geometries, thin walls, and intricate features that would be impractical or impossible with other manufacturing methods. For manufacturers specializing in custom aluminum alloy products, the aluminum die casting mould is not just a tool but a strategic asset, enabling the production of high-volume, cost-effective parts with consistent quality and minimal waste. The development process of an aluminum die casting mould involves rigorous testing and optimization, including computer-aided design (CAD) simulations to predict material flow and cooling patterns, as well as prototype testing to refine mould performance before full-scale production. This iterative approach ensures that the aluminum die casting mould can handle the unique properties of aluminum alloys, such as their high thermal conductivity and fluidity, while minimizing defects like porosity, shrinkage, and warpage. With the support of advanced equipment like coordinate measuring machines (CMMs) and X-ray real-time imaging detection systems, manufacturers can verify the dimensional accuracy and structural integrity of aluminum die casting moulds, ensuring they meet the stringent standards required for industries like automotive, where safety and reliability are paramount. Adhering to international certifications such as IATF 16949 further underscores the commitment to quality in aluminum die casting mould production, providing customers with confidence that each mould is engineered to deliver consistent, high-performance results. Whether for standard components or custom-designed parts, the aluminum die casting mould remains an indispensable tool in modern manufacturing, driving efficiency, innovation, and cost-effectiveness for businesses worldwide.