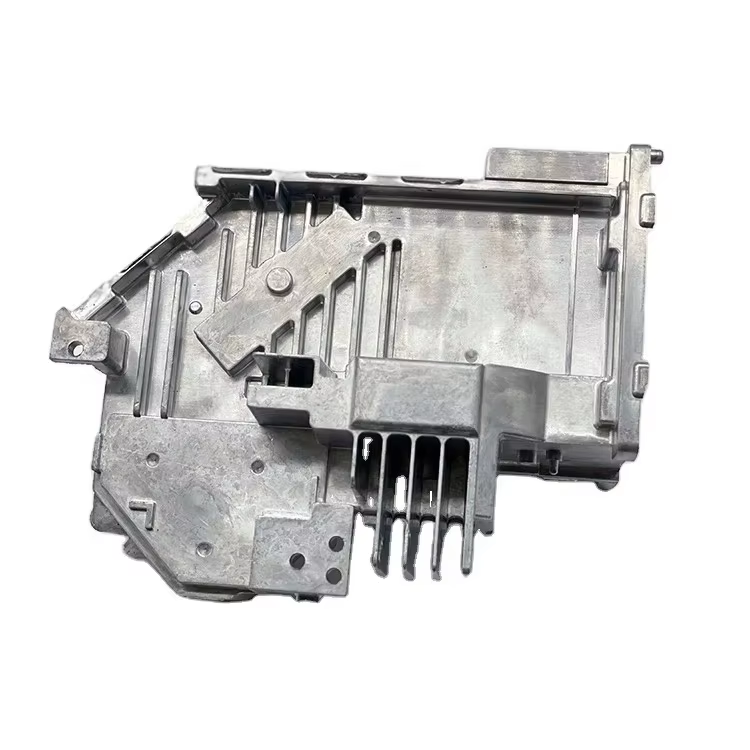

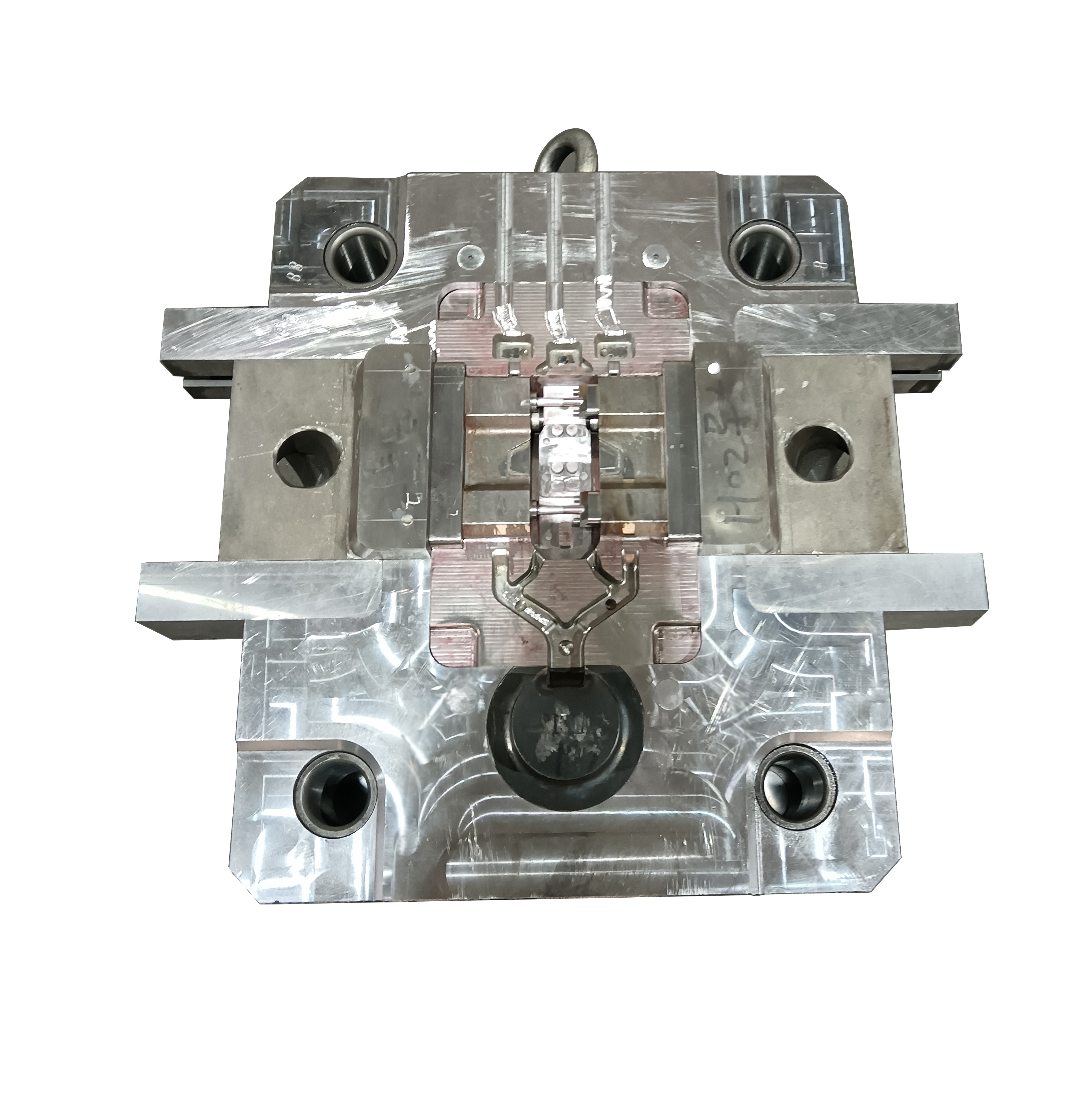

Aluminum die casting is a manufacturing process that involves forcing molten aluminum into a mold cavity under high pressure. This technique allows for the production of complex shapes and high-dimensional accuracy, making it a preferred choice for various industries, including automotive, aerospace, and electronics. At Haoda, we specialize in producing aluminum die casting parts that are not only lightweight but also exhibit excellent mechanical properties. Our state-of-the-art facilities are equipped with the latest technology, allowing us to maintain tight tolerances and achieve high-quality finishes on all our products. The versatility of aluminum die casting enables us to cater to a wide range of applications, from intricate components in consumer electronics to robust parts used in heavy machinery. Our commitment to innovation and quality ensures that we deliver solutions that meet the evolving demands of our global clientele. We understand that each project is unique, and therefore, we offer customization options to ensure that our aluminum die casting parts perfectly align with your specifications. Partner with us to experience the benefits of high-quality aluminum die casting solutions designed to enhance your product’s performance and reliability.