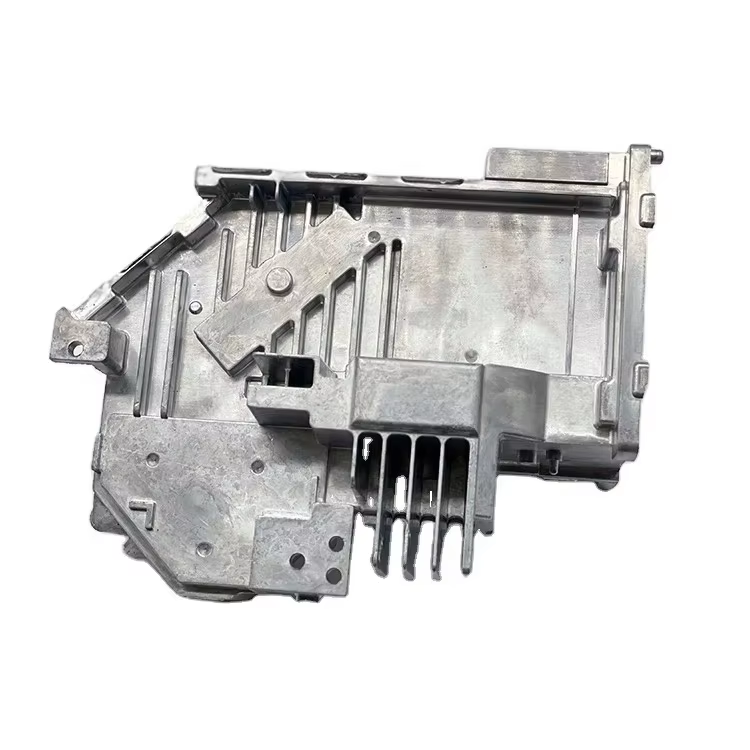

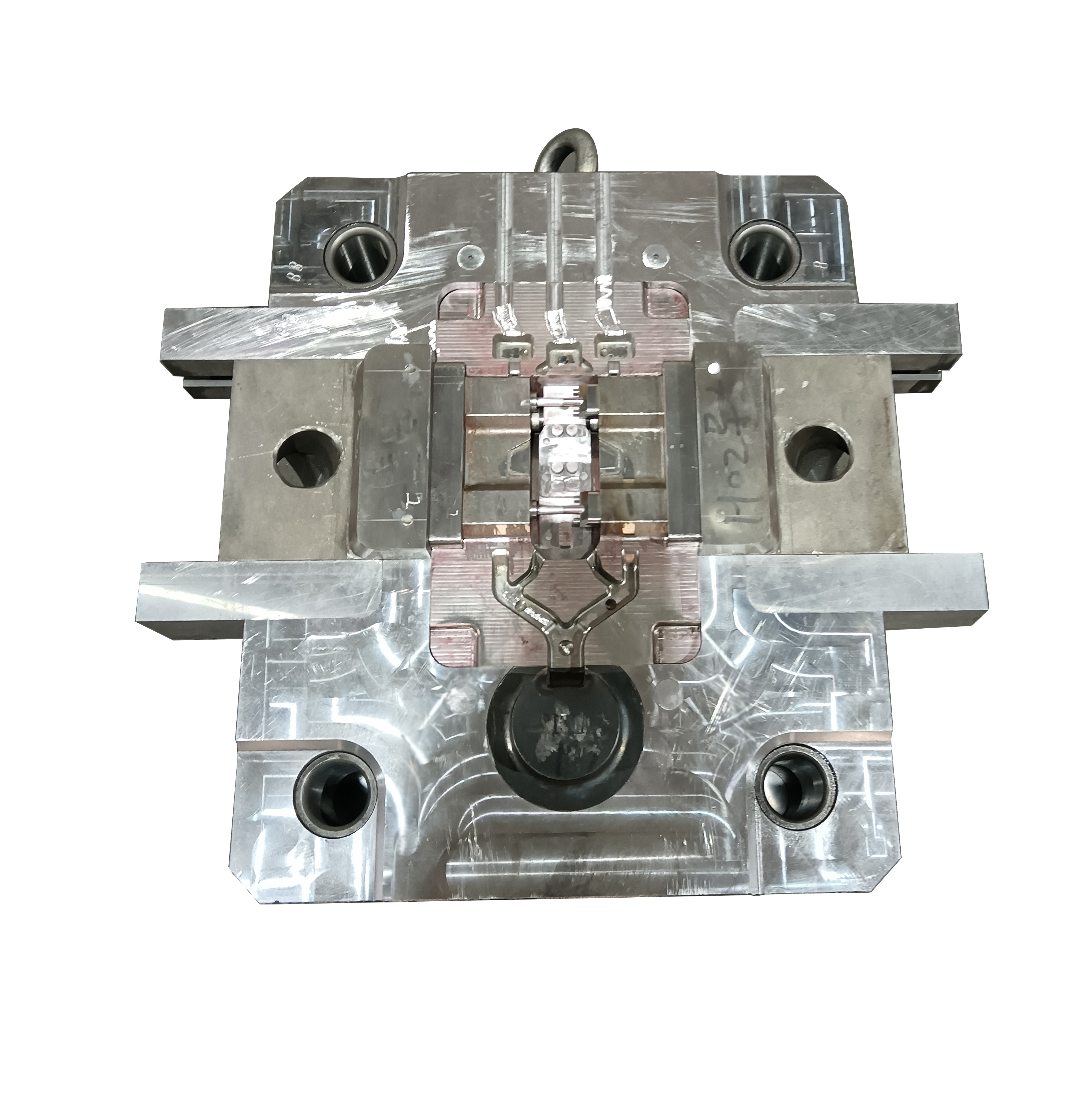

Aluminum die casting is a manufacturing process that involves forcing molten aluminum into a mold under high pressure. This technique allows for the production of intricate shapes and components with excellent surface finishes and dimensional accuracy. As a leading aluminum die casting supplier, Haoda (Ningbo) Import and Export Co., Ltd specializes in creating custom die-cast products that cater to a wide range of industries, including automotive, electronics, and consumer goods.

Our expertise in aluminum die casting enables us to offer lightweight yet durable components that can withstand harsh environments. The use of aluminum alloys not only enhances the mechanical properties of the final products but also contributes to cost-effective solutions for our clients. We prioritize innovation and continuously improve our processes to ensure that we meet the evolving demands of the market.

In addition to our die-casting capabilities, we also provide secondary operations such as machining, finishing, and assembly to deliver complete solutions. Our commitment to quality and customer-centric approach has positioned us as a reliable partner for businesses looking for high-performance aluminum die casting products. We invite you to explore our offerings and discover how we can help you achieve your project goals with our superior aluminum die casting solutions.