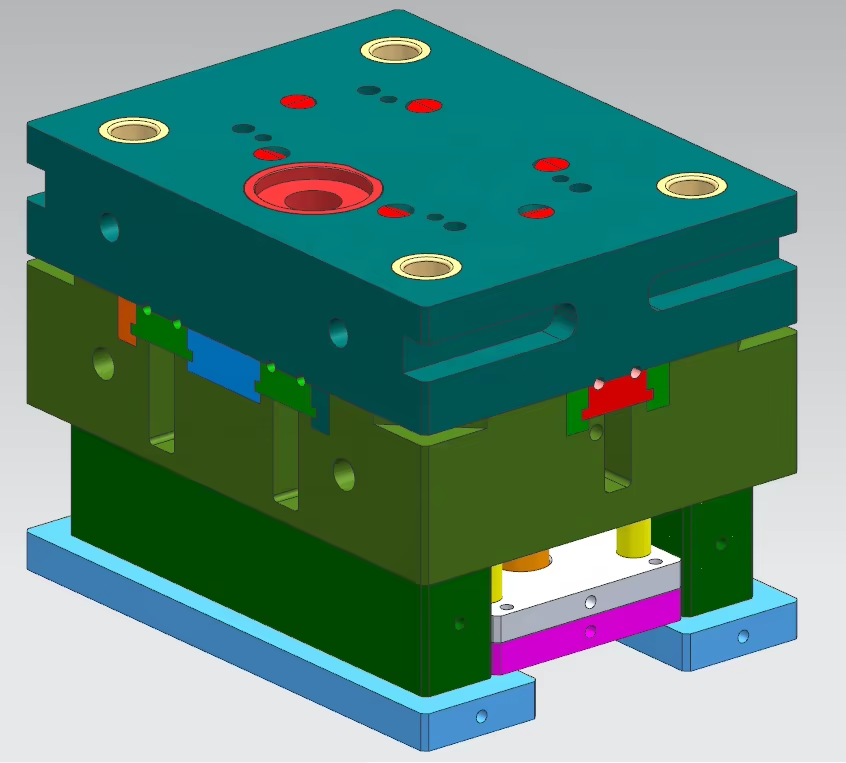

At Haoda (Ningbo) Import and Export Co., Ltd, we understand that the role of mold manufacturers extends beyond mere production. We specialize in creating customized solutions tailored to the needs of our clients across various industries. Our expertise in aluminum, zinc, and magnesium alloy products allows us to cater to diverse applications, from automotive components to consumer goods. Our state-of-the-art facilities are designed to handle complex projects, ensuring that every mold we produce meets stringent quality standards. We prioritize precision and durability, which are critical in today’s competitive market. Our team of skilled professionals works closely with clients to develop molds that not only meet their specifications but also enhance their product performance. By leveraging advanced technologies and adhering to international quality certifications, we guarantee that our molds deliver exceptional results. Whether you are looking for standard designs or bespoke solutions, our commitment to excellence positions us as a leader among mold manufacturers. We invite you to explore our capabilities and discover how we can help you achieve your production goals with efficiency and reliability.