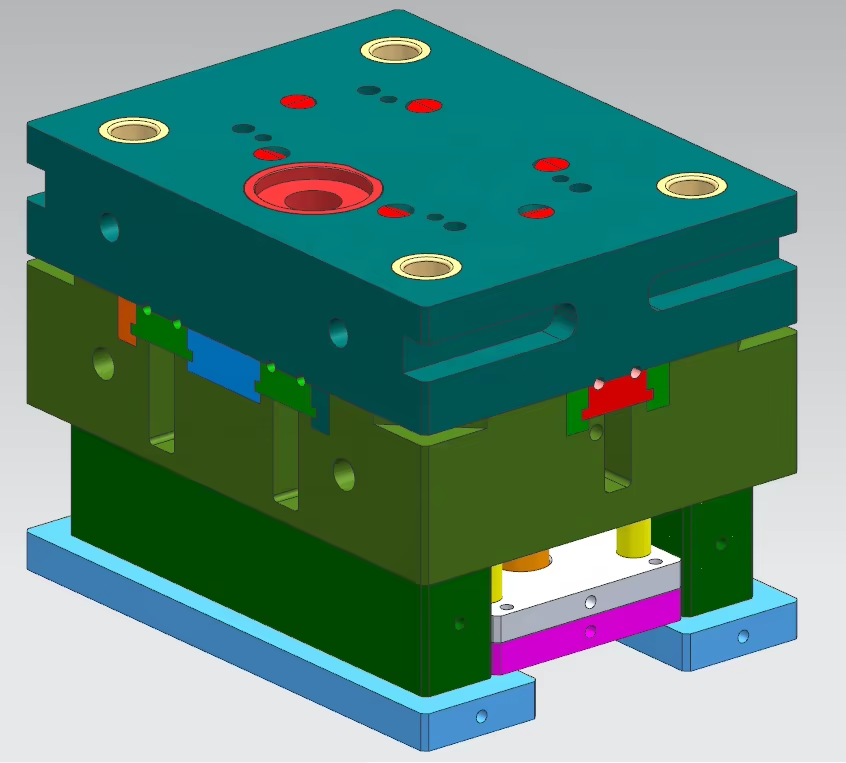

Mold manufacturing is a critical precursor to efficient, high-quality production in the casting and injection molding industries, requiring exceptional precision, engineering expertise, and attention to detail to create molds that consistently produce components meeting strict design specifications. Haoda (Ningbo) Import and Export Co., Ltd. excels in professional mold manufacturing, specializing in the design and production of custom molds tailored to the unique needs of aluminum, zinc, and magnesium alloy casting processes. Our mold manufacturing services combine advanced CAD/CAM design software with state-of-the-art machining equipment, ensuring that every mold is engineered for optimal performance, durability, and repeatability. The mold manufacturing process at our facility begins with a thorough analysis of client requirements, including component design, material properties, production volume, and tolerance specifications, allowing our team of experienced mold designers to develop a comprehensive mold design that maximizes efficiency and minimizes production defects. We utilize high-grade mold materials, carefully selected based on the casting process and expected production volume, to ensure that our molds withstand the rigors of repeated use—whether it’s high-temperature die-casting or precision investment casting—while maintaining dimensional stability and surface quality. What distinguishes our mold manufacturing services is the integration of advanced simulation tools that predict potential issues such as material flow, cooling efficiency, and shrinkage, allowing for design adjustments before mold production begins, reducing lead times and minimizing costly rework. Our mold manufacturing team comprises skilled toolmakers and engineers who bring decades of combined experience in crafting complex molds, capable of producing components with intricate geometries and tight tolerances that meet the demands of industries such as automotive, electronics, and machinery. We adhere to strict quality control measures throughout the mold manufacturing process, utilizing CMM inspections to verify mold dimensions and ensure alignment with design specifications, and conducting rigorous testing to validate mold performance before full-scale production. By maintaining compliance with the IATF16949 certification, our mold manufacturing services meet international quality standards, giving clients confidence in the reliability and consistency of the molds we produce. We offer end-to-end mold manufacturing solutions, from initial design and prototyping to mold production, testing, and maintenance support, ensuring that clients receive comprehensive assistance throughout the lifecycle of their molds. Our flexible mold manufacturing capabilities allow us to accommodate both small-batch and large-scale production needs, with the ability to adjust designs quickly to meet evolving client requirements. By investing in the latest mold manufacturing technology and continuous training for our team, we stay at the forefront of industry advancements, offering innovative solutions that improve production efficiency, reduce cycle times, and lower overall manufacturing costs for our clients. As a trusted partner in mold manufacturing, we are committed to delivering high-quality, custom-engineered molds that serve as the foundation for successful production, fostering long-term relationships built on technical excellence, reliability, and mutual success.