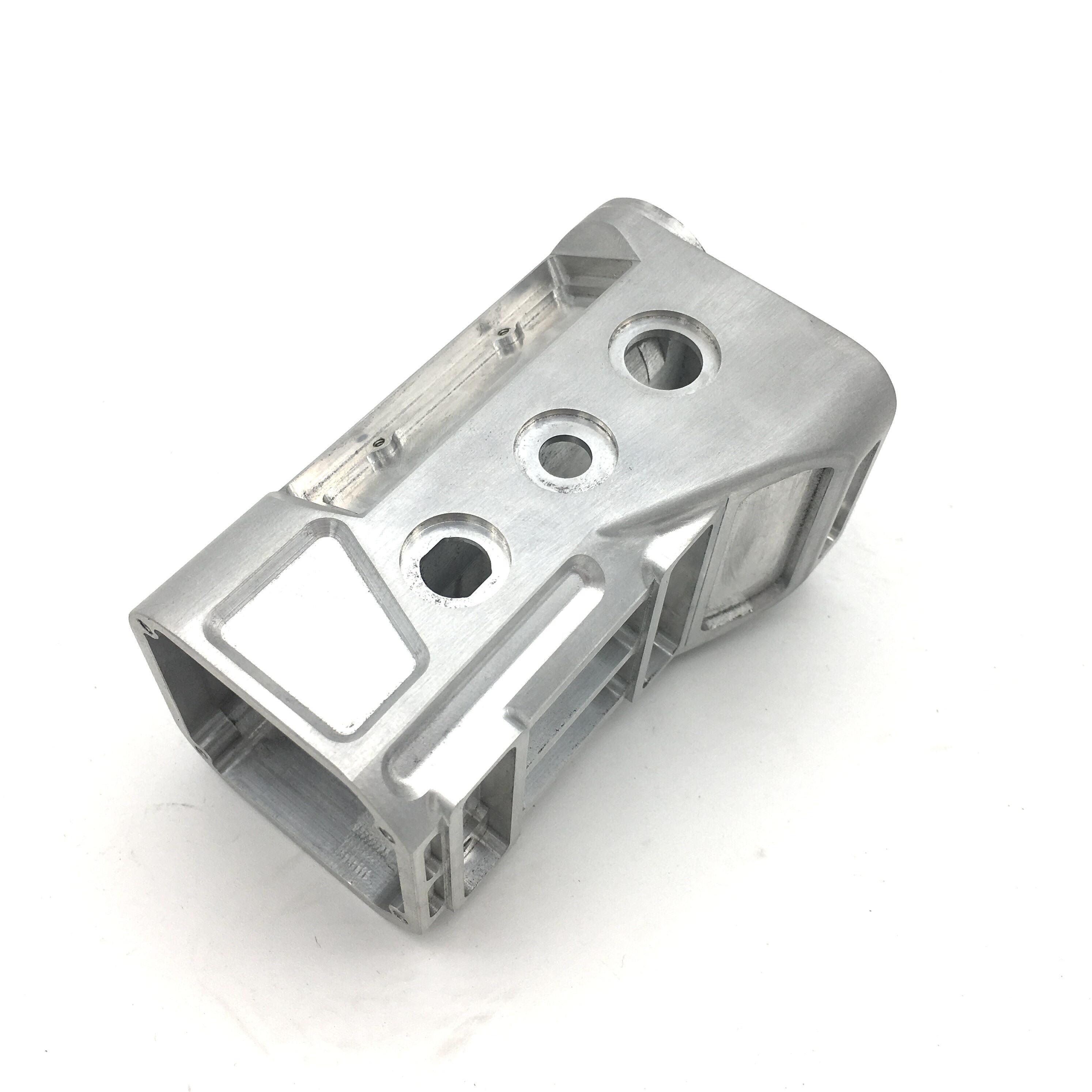

Aluminum bars are essential components in numerous industries, known for their lightweight, strength, and corrosion resistance. At Haoda (Ningbo) Import and Export Co., Ltd, we specialize in providing high-quality aluminum bars that cater to a wide range of applications. Our aluminum bars are produced using advanced techniques, including automatic melting and die-casting, ensuring superior quality and precision. The versatility of aluminum makes it an ideal choice for manufacturing parts in automotive, aerospace, construction, and many other sectors. Our team of experts is dedicated to working with clients to understand their unique needs, allowing us to deliver customized solutions that enhance operational efficiency. With our focus on quality control and customer satisfaction, you can trust that our aluminum bars will meet and exceed your expectations. We pride ourselves on our competitive pricing, ensuring that you receive value without compromising on quality. Partner with us today to discover how our aluminum bars can elevate your projects.