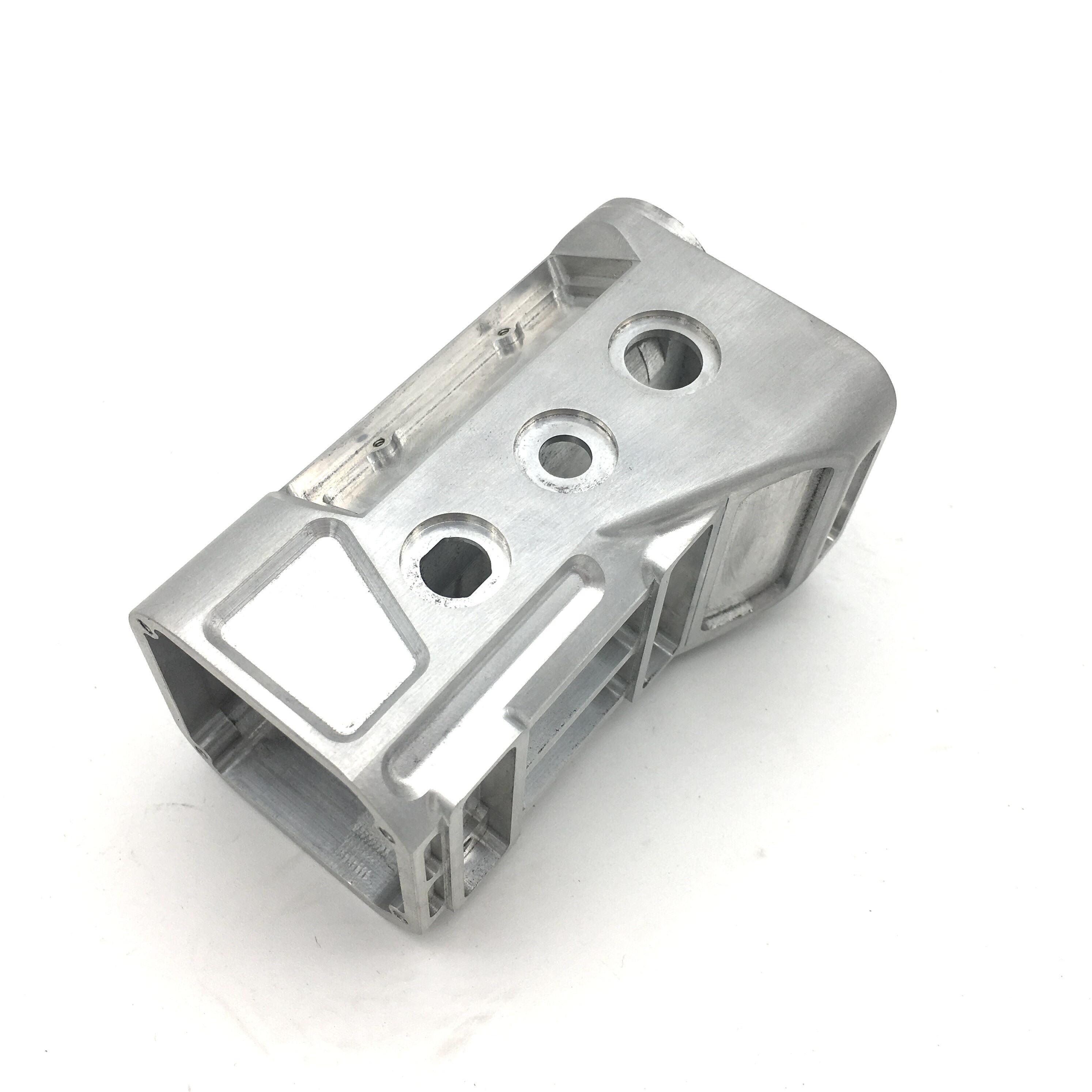

Aluminium boxes are essential components in various industries, offering a combination of lightweight properties, strength, and resistance to corrosion. At Haoda (Ningbo) Import and Export Co., Ltd, we specialize in producing high-quality aluminium boxes that cater to a wide array of applications. Our products are designed to withstand harsh conditions, making them ideal for both indoor and outdoor use.

The versatility of aluminium boxes makes them suitable for industries such as electronics, automotive, aerospace, and logistics. Our aluminium boxes can be customized in size, shape, and features, including locking mechanisms, handles, and ventilation options, to meet specific client needs. With our advanced manufacturing capabilities, we ensure precision and consistency in every product, which is crucial for industries requiring high standards.

Moreover, our commitment to sustainability means that our aluminium boxes are not only durable but also environmentally friendly. Aluminium is a recyclable material, reducing the overall carbon footprint of our products. By choosing our aluminium boxes, clients can contribute to a more sustainable future while benefiting from high-quality, reliable solutions for their storage and transport needs.