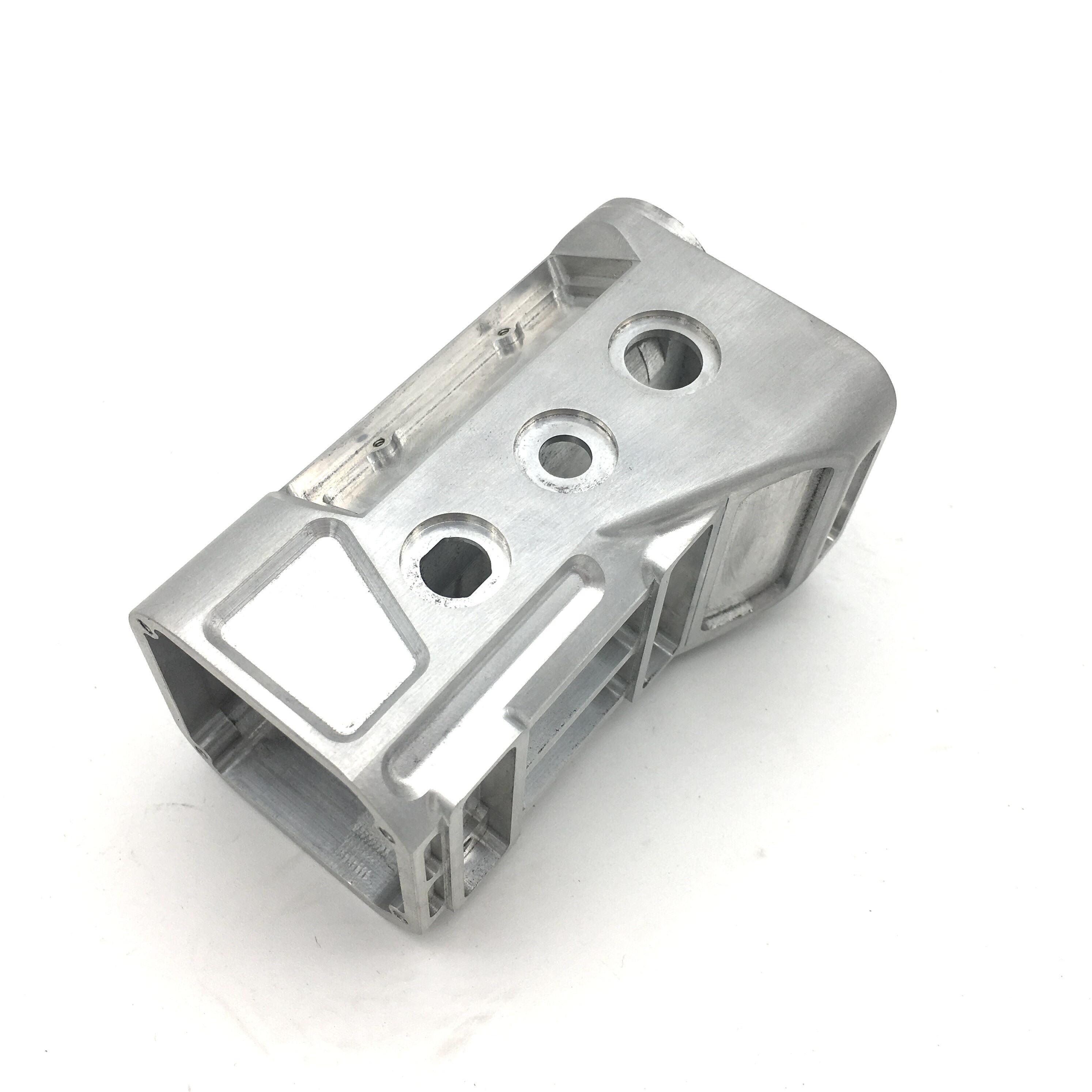

Aluminum products are at the forefront of modern manufacturing due to their lightweight, strength, and corrosion resistance. At Haoda, we focus on delivering high-quality aluminum solutions that cater to various industries, including automotive, aerospace, electronics, and construction. Our state-of-the-art production facilities enable us to create custom aluminum products that not only meet but exceed industry standards. We utilize advanced techniques such as die-casting and CNC machining to ensure precision in every piece we produce. Our commitment to sustainability is reflected in our processes, as we strive to minimize waste and maximize efficiency. This makes our aluminum products not only a smart choice for performance but also for environmentally conscious businesses. By partnering with us, you gain access to a wealth of expertise and a dedication to quality that ensures your projects succeed.