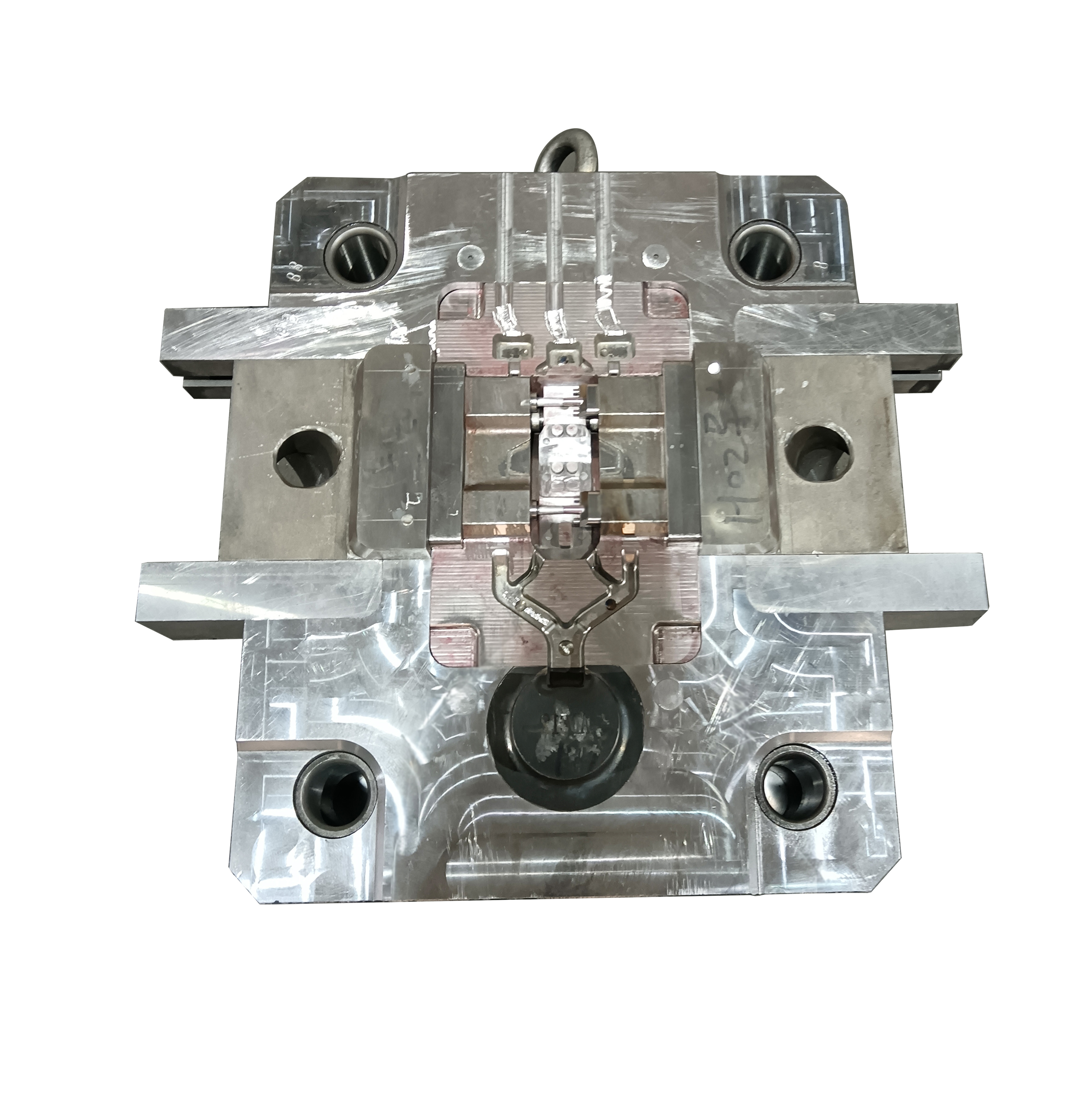

Zinc die casting is a manufacturing process that allows for the production of complex shapes with high dimensional accuracy and surface finish. At Haoda, we specialize in the production of zinc die casting components that are widely used in various industries, including automotive, electronics, and consumer goods. Our components are made from high-quality zinc alloys, which offer excellent corrosion resistance, strength, and durability. The die-casting process involves injecting molten zinc into a mold under high pressure, resulting in precise and consistent parts that can be easily machined or finished as needed.

Our zinc die casting components are ideal for applications that require lightweight yet strong materials. The versatility of zinc alloys allows for various surface treatments, including plating, painting, or powder coating, to achieve the desired aesthetic and functional properties. With our advanced production capabilities, we can handle both small and large volume orders, ensuring timely delivery without compromising quality. Our focus on innovation and customer satisfaction drives us to continually improve our processes and products, making us a leader in the zinc die casting industry.