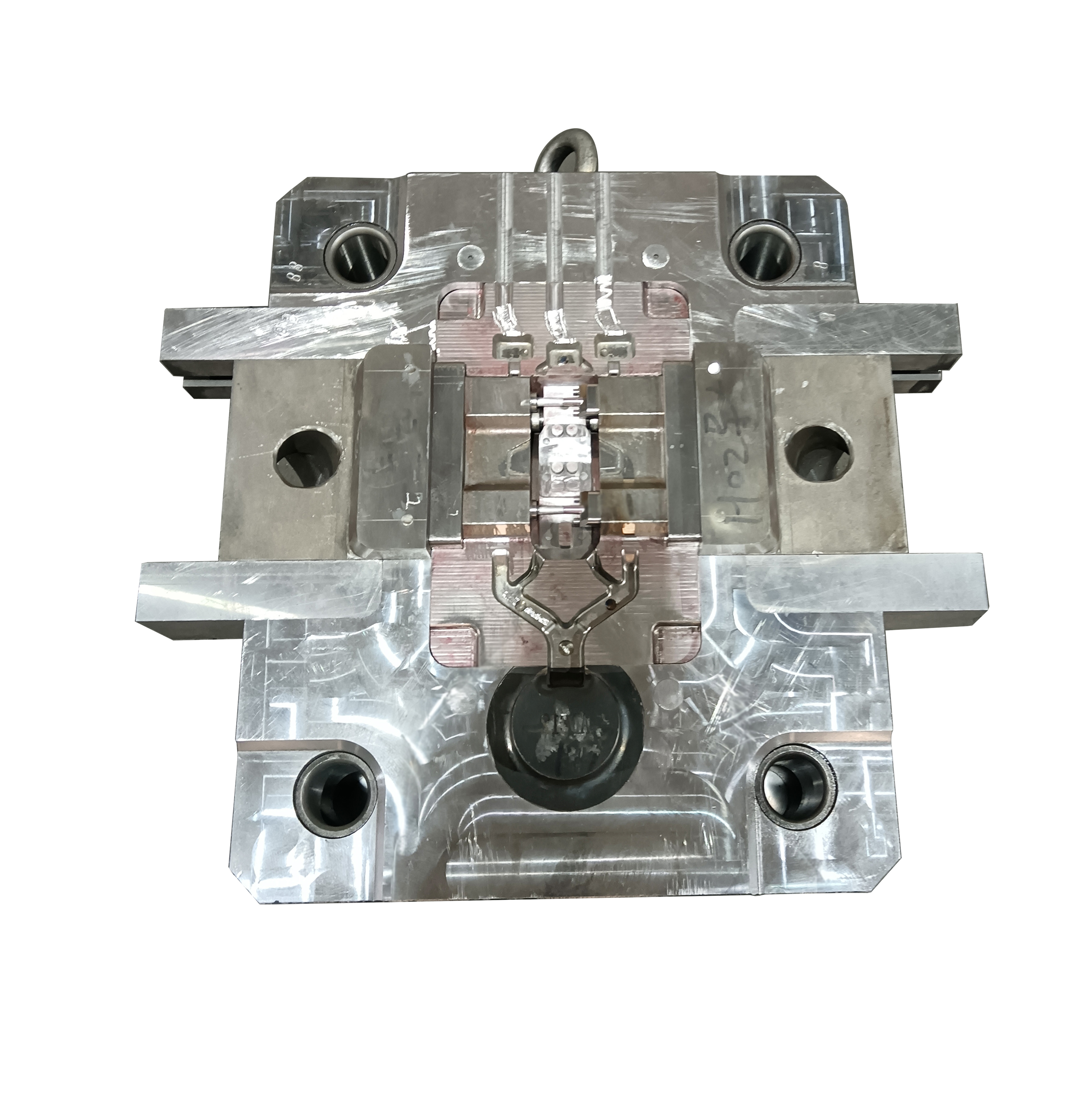

Precision die casting is a manufacturing process that involves forcing molten metal into a mold cavity under high pressure. This method is particularly effective for producing complex shapes with high dimensional accuracy and a superior surface finish. At Haoda (Ningbo) Import and Export Co., Ltd, we specialize in precision die casting parts made from aluminum, zinc, and magnesium alloys. These materials are chosen for their excellent mechanical properties, lightweight nature, and resistance to corrosion.

Our precision die casting parts are widely used in various industries, including automotive, electronics, and consumer goods. The versatility of the die casting process allows us to create intricate designs that meet the specific needs of our clients. The high-speed production capabilities of our automatic machines enable us to deliver large quantities of parts quickly, making us an ideal partner for both small and large-scale projects. Additionally, our commitment to quality is evident in our adherence to IATF16949 standards, ensuring that every part we produce is of the highest quality. We also employ advanced inspection techniques, such as CMM and X-ray real-time imaging, to guarantee that our products meet the strictest quality criteria.